How Do Brushless DC Electric Motors Work?

Brushless DC motors are commonly used across the world. At the most basic level, there are brushed and brushless motors and there are DC and AC motors. Brushless DC motors, as you may imagine, do not contain brushes and use a DC current. These motors provide many specific advantages over other types of electrical motors. But how do brushless DC electric motors work beyond the basics?

What is a brushless DC motor?

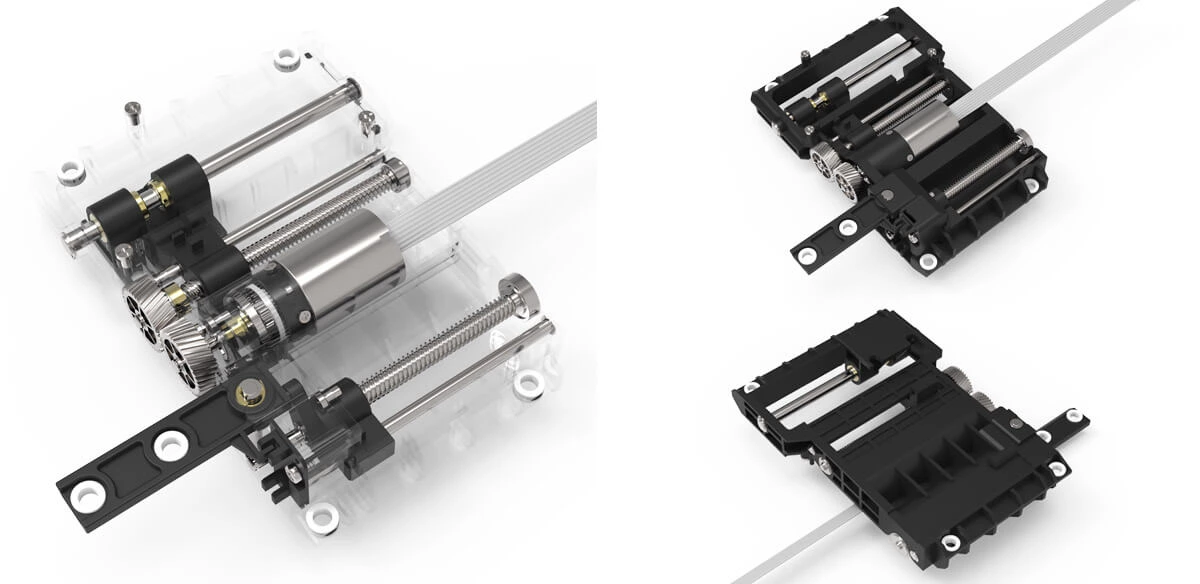

Brushless DC electric motors (BLDC motors, BL motors), also known as electronically commutated motors (ECMs, EC motors), are synchronous motors that are powered by a DC electric source via an integrated inverter/switching power supply. Efficiency is a primary selling feature for BLDC motors. Because the rotor is the sole bearer of magnets, it requires no power. This means there are no connections, no commutator, and no brushes. In place of these, the motor uses control circuitry. To detect where the rotor is at certain times, BLDC motors use, along with controllers, rotary encoders or a Hall sensor. ZHAOWEI designs, develops and manufactures a series of small brushless DC motors with voltage ranging from 3V to 24v.

How do brushless DC electric motors work?

A brushless DC motor is composed of the motor body and the brushless DC motor driver. The stator of the brushless DC motor is the coil winding armature and the rotor is the permanent magnet. If electrified with a fixed DC, the motor can produce a constant magnetic field and does not rotate. When the rotor position is being detected in real time, the stator can generate a rotating magnetic field with a uniform change in the direction according to the position of the rotor which makes it possible to provide the corresponding current. In this way, the motor can rotate following the magnetic field. Actually, with BLDC motors, it’s the permanent magnet that rotates. To control the rotation, all you need to do is adjust the magnitude and direction of the current into these coils. Also, if the brushless DC-motor is integrated with a brushless DC motor controller, it will combine the advantages of brushless DC motors and their electronic control. Controller settings can be configured in combination with motion manager through programming adapters.

Brushless DC electric motors have several kinds of advantages owing to the working principle.

- 2.1 One big advantage is efficiency, as these motors can be used continuously at maximum rotational force (torque). Brushed motors, in contrast, reach maximum torque at certain points in the rotation. Brushless DC electric motors typically have an efficiency of 85-90%, while brushed motors have efficiency rates of 75-80%. Brushless DC motors with planetary gearheads can also provide higher torque.

- 2.2 The second big advantage—related to the first—is controllability. BLDC motors can be controlled, using feedback mechanisms, to deliver precisely the desired torque and rotation speed. Precision control, in turn, reduces energy consumption and heat generation, thus lengthening the service life.

- 2.3 Brushless DC motors are quiet, lighter and have much longer lifespans, thanks to the lack of brushes. With brushed motors, the brushes and commutator wear down as a result of continuous moving contact, and also produce sparks where contact is made. Electrical noise, in particular, is the result of the strong sparks that tend to occur in the areas where the brushes pass over the gaps in the commutator. When comparing brushless motors to motors with brushes, it becomes clear that this is why BLDC motors are often considered preferable in instances avoiding electrical noise is important.

What can they be used with?

We've seen that BLDC motors offer high efficiency and a strong ability to control while also having long operating lives. In many instances, however, brushless DC electric motors alone are not enough. Planetary gearheads also play an important role. Brushless DC gear motors are often used in modern devices where high torque, low noise and long service life are required. Brushless DC motors assembled with gear motors are is widely used in massage machines, fitness equipment, robotic equipment, speakers, vacuum cleaners, etc. Gear motors by ZHAOWEI that have seen increased popularity include:

- Brushless DC Motor for Hot Pot Cooker

- Brushless DC Motor for Vacuum Cleaners