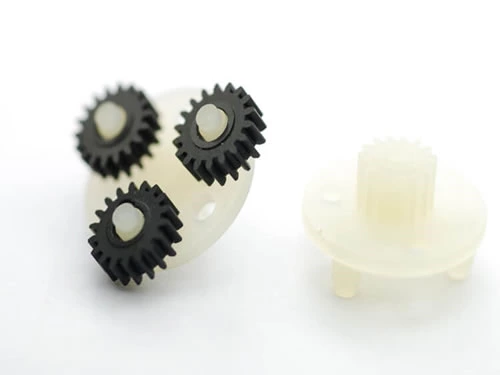

Why Choose Plastic Geared Motor?

Depending on the material used, geared motors are divided into plastic and metal types, based on the material of the housing. While our metal gears also include power metallurgy and hardware processing, both types of gears have their own advantages and limitations. Here are some reasons for choosing plastic geared motors.

1. Lower cost: Generally, the production cost of plastic gears is cheaper than that of metal gears. Since there is usually no need for secondary finishing, plastic gears typically account for savings of 50% to 90% compared to stamped or machined metal gears.

2. Low noise: Strong shock absorption performance of plastic gear motors contributes to their low noise during operation.

3. High degree of design freedom: Molding plastic offers more efficient gear geometries than metal. Molding is ideal for creating shapes, such as internal gears, cluster gears, and worm gears where the cost for forming them in metal can be prohibitive.

4. High precision: Plastic gears can achieve high precision with consistent material quality and precise molding process control.

5. Strong bearing capacity: Since plastic gears can be wider than metal gears, they can achieve greater load-bearing capacity and more power transfer in a single stage.

6. Corrosion resistance: Unlike metal gears, plastic gears do not corrode because they are nonconductors. Their relative inertia means they can be used in water meters, chemical plant controls, and other situations that may cause corrosion or degradation of metal gears.

7. Lubrication: The inherent lubricity of many plastics makes them very suitable for computer printers, toys, and other low-load situations that require dry gears. Plastics can also be lubricated with grease or oil.

8. Lightweight: The weight of plastic gear is often lighter than that of metal gear.

9. Good shock absorption performance: Plastic gears have more bearing force than metal gear because plastic can deflect to absorb impact load. It also does a better job of distributing localized loads caused by misalignment and tool errors.

Limitations of Plastic Gears

When compared with metal gears, plastic gears have the limitations of low modulus of elasticity, low mechanical strength, poor heat conduction performance, and a large coefficient of thermal expansion. Temperature is the main factor affecting wear, and rotation speed and transmission torque are more important factors affecting tooth surface temperature and wear, which limit the use of plastic gears in high load and high-speed occasions.