What is DC Motor Torque?

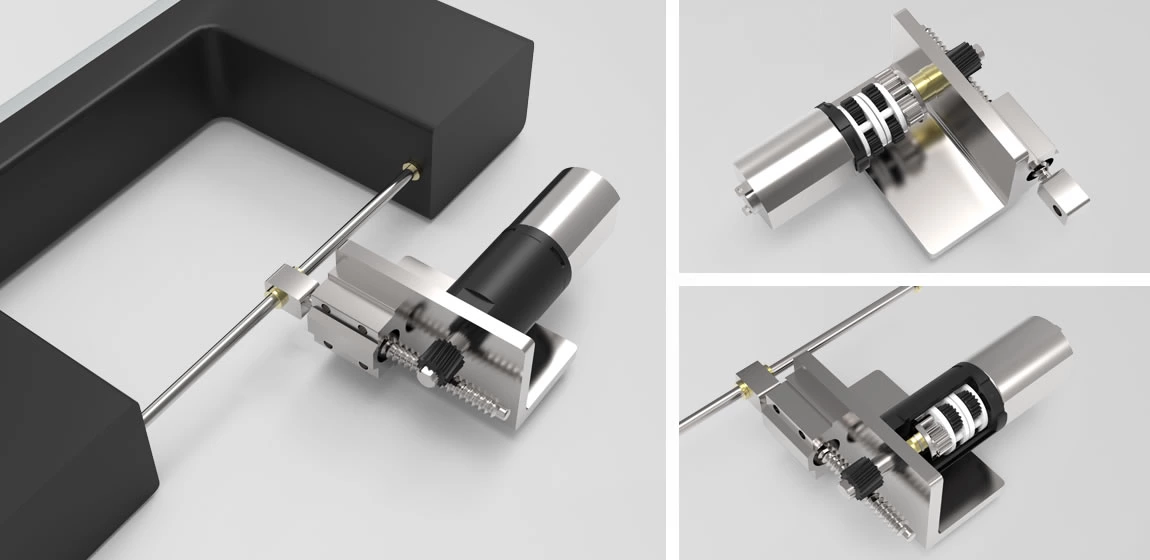

Are you considering a DC motor for your next project? If so, we’re here to provide all the help and advice you need before investing. A DC motor is powered through direct current, meaning the current flows in one direction only. When selecting which motor to be used, the torque needed becomes one of the parameters to be considered. ZHAOWEI drives combined with suitable encoders are strongly suited for applications where high torque and low RPM is required in compact spaces.

What is DC motor torque?

A torque motor is a specialized form of DC electric motor which can operate indefinitely while stalled without incurring damage. In this mode of operation, the motor will apply steady torque to the load (hence the name). A torque motor that cannot perform a complete rotation is known as a limited angle torque motor. A high torque DC motor offers a high starting torque, which makes it ideal for use in applications that are designed to move heavier loads, such as wiper systems and industrial automation applications, such as conveyor systems or material handling equipment. The consistent drive power that DC motors deliver means they’re ideal for maintaining a constant torque whilst in use, making them a great choice for gear drive systems. When the DC motor doesn’t include a gearbox, the DC motor torque is different from the DC geared motor torque. Gears make it possible to reach higher torque.

Take 3.4MM high torque DC gear motor (ZHAOWEI) as an example; its DC motor torque is 0.06 - 4.12mN.m, but when it is geared, its torque may get higher.

ZHAOWEI offers a series of high torque geared DC motors with an output torque between 1.0 gf.cm and 50 kgf.cm. Further strengths of the motor are its low power consumption, high energy-efficiency, minimal vibration and low audible noise. They are therefore suited to be used as drives for applications with small dimensions and high requirements, such as for precision tools, optical devices, or active prostheses.

High Torque Geared DC Motor

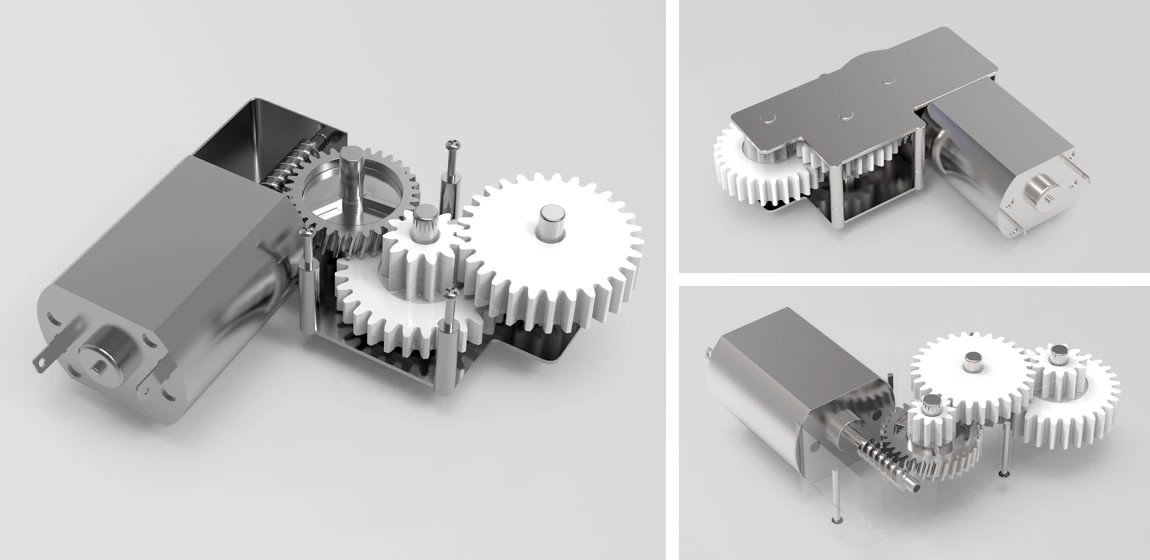

Just as the name implies, sometimes, the motor that needs high torque should be geared. When a rotary machine such as an engine or electric motor needs the output speed reduced and/or torque increased, gears are commonly used to accomplish the desired result. The gear ratio expresses the ratio of the output torque to the input torque. Thus, we can multiply the torque supplied at the motor shaft (the input) by the gear ratio to find the torque at the wheel axle (the output). Transmitting power through a series of gears can also affect rotational speed. In other words, when a rotary machine such as an engine or electric motor cannot provide the desired output speed or torque, using a gear reducer may be a suitable option.

High torque geared DC motors provided by ZHAOWEI include 3.4MM, 4MM, 6MM, 8MM, 10MM, 12MM, 16MM, 20MM, 20MM, 24MM, 28MM, 32MM, 38MM types.

Features

- Permanently lubricated ball bearings

- High torque-to-inertia ratio and high torque in a “small package” size

- Low noise and backlash

- Long service life

- Gear ratio from 5 to 1500 and output torque from 1.0 gf.cm to 50 kgf.cm to achieve high torque and low RPM

- High energy / high power in compact space

- Gear structure for highly controllable speed

- Custom services for specific needs

In some industries, it is vital that DC motors can operate efficiently at an ideal speed to meet the requirements of the application. If you’re looking for a system that offers high torque with gears, a DC motor supported by ZHAOWEI is a good choice.