Differences of Small Gear Motors

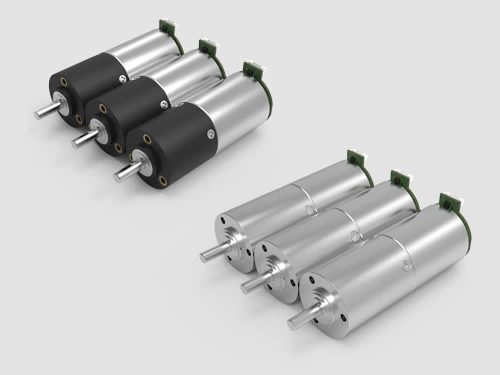

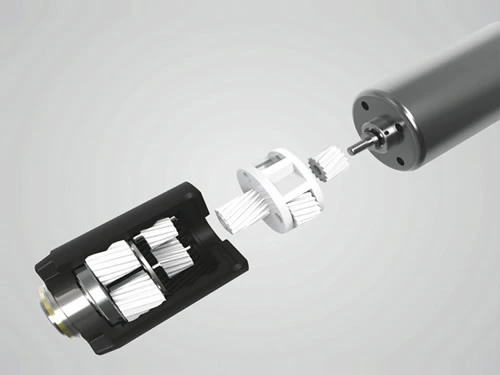

Since there are so many types of gear motors, it’s easy to get confused when talking about them. When it comes to small gear motors, there are some basics we need to know to be able to distinguish them. For starters, the micro gear motor is a combination of a micro gearbox (reducer) and an electric motor. With this gear reducer system, the gear motor can be used for low speed and high torque applications. Based on the motor used, gear motors can be categorized into small brushless DC motors, small brushed DC motors, micro stepper gear motors, servo gear motors, and more. But what are their differences? This passage will compare these similar gear motors and explain them in detail. Differences will be described in sets; small brushed DC gear motors and small brushless DC gear motors, plus small stepper gear motors and small servo gear motors.

Small Brushed DC Gear Motors vs Small Brushless DC Gear Motors

The main difference between a small brushed DC gear motor and a small brushless DC gear motor lies in the motor: one is the brushed DC motor and the other is the brushless DC motor.

1.Scope of Application

Brushless DC Gear Motors are usually used for equipment with relatively high control requirements and relatively high speed, such as aircraft models and precision instruments, which have higher requirements for motor speed and high-speed control. Small DC motors with brushes are usually used for power equipment, such as hairdryers and household range hoods. In addition, brushed DC motor can reach higher speeds. However, due to the wear of the carbon brushes, the service life of brushed motors is not as long as brushless motors.

2. Service Life

Small brushless DC motors: the service life is several tens of thousands of hours, but it may differ due to different bearings. Small DC motors with brushes: Generally, the continuous working life of a brushed motor is about 1,000 hours. When the use limit is reached, the carbon brush needs to be replaced or it will cause bearing wear.

3.Use effect

Small brushless DC motors: Digital frequency conversion control technology is generally adopted, enabling strong controllability. The speed can vary from a few revolutions per minute to tens of thousands of revolutions per minute. Small DC motors with brushes: The old carbon brushed motor generally works at a constant speed after starting, and speed adjustment is not easy. Brushed DC motors can also reach 20,000 rpm, but the service life is relatively short.

4. Energy Saving

Relatively speaking, brushless motors controlled with inverter technology will save much more energy than brushed DC motors.

5. Maintenance

The carbon brush needs to be replaced after long-term use, and brushed motors will be damaged if it is not replaced quickly. Brushless motors have a relatively long service life, usually more than 10 times that of brushed motors. Brushless DC motors don’t require daily maintenance. If they break, the motor needs to be replaced.

Small Stepper Gear Motor VS Small Servo Gear Motor

1. Control Method

The control methods of stepper gear motors and servo gear motors are different. For micro metal geared stepper motors, the rotating angle is determined by the pulse number. Each pulse corresponds to a step angle. However, there is no feedback signal, which results in the accurate rotating position of the motor being unknown and the position accuracy is not high enough. The servo gear motor controls the rotating angle by the number of pulses as well. What differentiates them is their feedback signal. Each time the servo motor rotates at a certain angle, the corresponding number of pulses will be sent. At the same time, the drive will receive the feedback signal and compare it with the pulse received by the servo motor, allowing system to analyze the difference in pulse number. The rotation of the motor can be controlled very accurately, so as to achieve precise positioning, which can reach 0.001mm.

2. Overload Capacity

Stepper motors generally do not have overload capacity while an AC servo motor has a strong overload capacity. Take the Pilz servo system as an example. It has speed overload and torque overload capabilities and its maximum torque is 3 times the rated torque, which can be used to overcome the instant inertial load at the starting moment.

3. Response Time

The response speed performance between both motors is different. It takes 200–400ms for a micro metal geared stepper motor to accelerate from a standstill situation to a working speed (generally several hundred revolutions per minute). The acceleration performance of the AC servo system is better. Take the Pilz AC servo motor as an example; it takes a few minutes to accelerate from standstill to its rated speed of 3000 r/min. It can be used for applications where fast starting and stopping and high position accuracy is required.

After reading the detailed contrast of general small gear motors, we hope it’s easier to select a suitable gear motor for your specific use. ZHAOWEI provides different types of brushed DC motors, BLDC gear motors, servo gear motors, and stepper gear motors of different specifications. Parameters, such as diameter, voltage, speed, reduction ratio can be customized.