How Does A DC Motor Work?

When it comes to a DC motor, one might wonder what a DC motor is and how it works. A DC (Direct Current) motor is an electric motor that supplies power to machines as it uses electrical energy to perform its primary function. Alternatively, it is a rotating electrical device that converts the direct current of electrical energy into mechanical energy. A DC motor is usually divided into two types—brushed DC motor and brushless DC motor (BLDC). Regardless of the type of DC motor, ZHAOWEI provides you options with gearboxes. Just as the name shows, their main difference is whether the motor owns the brush.

Today, brushless motors are far more common than brushed ones; however, both can be found in a broad range of applications. Brushed DC motors remain commonly used in home appliances and automobiles. Brushless DC motors have been extended to many applications owing to their reliability and durability. They are commonly used in a broad spectrum of industries—manufacturing, computing, and so on. Indeed, the new generation of electric vehicles and even some power tools are using them. Owing to vastly different needs and environments, motion control projects can benefit from either motor.

How does a DC Motor work?

Whether it is a brushed DC motor or BLDC, the principle behind the internal working of both are essentially the same. The fundamental working principle of a DC motor is, “whenever a current-carrying conductor is placed in a magnetic field, it experiences a mechanical force.” However, nowadays, DC motors adopt permanent magnets, which feature higher safety, energy efficiency, simple control of motor speed, and low cost. Hence, more people are preferring Permanent-Magnet DC Motors. During operation, there remain some similarities and differences between how brushed motor and BLDC work.

Similarities:

- For constructing any DC motor, it is essential to establish a magnetic field, which, in turn, is established by using a magnet. You can use different types of magnets, for example, a permanent magnet. A Permanent-Magnet DC motor (PMDC motor) is a type of DC motor that uses a permanent magnet to create the magnetic field required to operate a DC motor.

- In such two types of DC motors, an armature rotates inside a magnetic field. Both follow the basic working principle, which is based on the fact that whenever a current carrying-conductor is placed inside a magnetic field, mechanical force is experienced by that conductor.

Differences:

- The working principle of the brushless DC permanent magnet motor is based on the force exerted by the current conductor in the magnetic field, whereas the working principle of the brushless DC permanent magnet motor is different, which is pulled by force between the stator magnetic field and the rotor magnetic field.

- In the brush PMDC motor, the current is transferred to the coils of the commutator by metallic brushes, which rotate along with the rotor. However, how does a brushless DC motor controller work? BLDC motor does not use carbon brushes or a mechanical commutator (may reduce losses), which might require an electronic controller or microprocessor to coordinate the current.

- Compared with the brush PMDC motor, the permanent magnet of the brushless PMDC motor is mounted on the rotor.

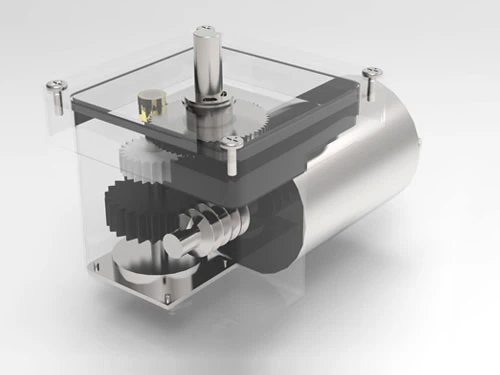

DC Motor: with Gear or without Gear

When is it compulsory to choose the DC motor with gears? A DC motor without a mechanical gearbox is a viable power source in a broad range of applications where the motor’s shaft speed is not an issue. Take the fan in our daily life as an example; in most cases, the faster a fan can spin, the better it is at accomplishing its task (moving air to cool a space or components). Thus, the shaft speed of a DC motor does not cause an issue. However, in other applications where shaft speed must be controlled, a DC motor alone might not be an ideal choice. Applications like automatic sliding doors or turntables in microwave ovens need a mechanical gearbox to decrease the motor’s shaft speed to a value that is easy to manage and easy to control.

Whether a DC motor should be equipped with or without gears varies from application to application. Compared with standard DC motors, those with gearboxes not only provide essential benefits when it comes to creating goods but also aid in the systems’ maintenance. Using a gearbox to multiply torque, match inertia, and reduce speed facilitates cut systems operations by letting smaller motors and drives be utilized.

Besides selling standard products, ZHAOWEI provides design, research, and manufacture for customers based on their specific needs.