How to Calculate the Torque of Gear Motor?

The power and speed determine the torque of the gear motor. The rated output torque of the gear motor is determined by its rated transmission power and rated output speed, and its actual output torque is determined by its actual transmission power (load size) and the actual output speed. You must choose a suitable gear motor and improve the product’s safety during use, avoid overload use. If the rated output torque of the gear motor is not sufficient, the working machine will fail to run. You can replace the gear motor and select the gear motor with larger rated power or invariant rated power and low output speed.

Torque Calculation Requirements:

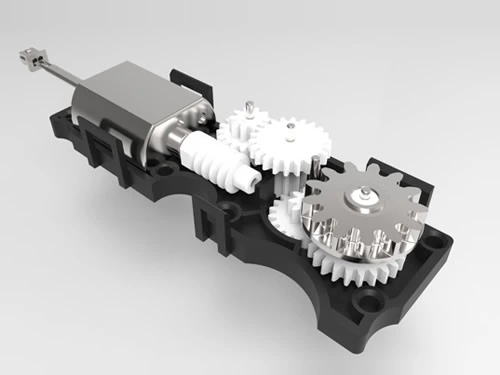

To prolong the service life of the gear motor, the calculation of torque is essential, which must pay attention to whether the maximum torque (TP) of acceleration exceeds the maximum load torque of the gear motor. Different stages of gear motors have different output torques; they are often divided into three types based on stages: one-stage gear motor (usually <10:1), two-stage gear motor (usually >10:1 and ≤200:1), and three-stage gear motor (some brands have no three-stage option; maximum reduction ratio is 100:1; it is >100:1.) The gear motor is possible to reach five-stage with the maximum reduction ratio of 4592:1.

The Formula of Gearbox Torque Calculation:

Reduction ratio = motor output revolutions/reducer output revolutions (“reduction ratio” is also called “gear ratio”)

1. The motor power, ratio, and service factor are given. Calculate the gearbox torque via the following formula:

Gearbox torque = 9550 × motor power ÷ motor power input revolution ÷ reduction ratio ÷ use coefficient

2. The torque, output revolution of the gearbox, and use coefficient are given. Calculate the motor power of the gearbox via the following formula:

Motor power = torque ÷ 9550 × motor power input speed ÷ reduction ratio ÷ use coefficient.