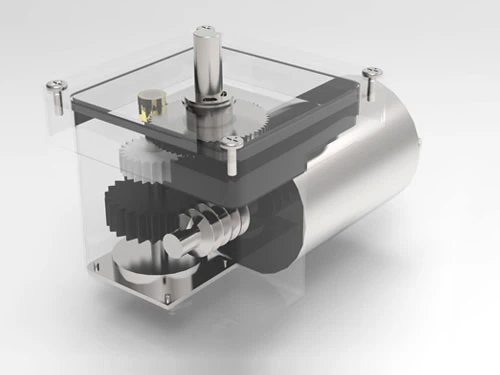

Key Points of Gear Motor Assembly

Gear transmission refers to devices that transmit movement and power by meshing the driving gear and driving gear directly. The gear motor transforms the high-speed rotation of the motor into the lower speed and higher torque needed in mechanical equipment primarily by using several pairs of gears. Thus, it is usually installed between the prime mover and the working machine to decrease the speed and transmit torque. Through increasing practice of gear motor assembly, the analysis and summary of common problems in the gearbox assembly procedure are beneficial to find problems quickly and precisely in daily work and manage them timely, thereby improving assembly accuracy and overall machine quality.

Brief description of the gearbox assembly procedure

1.1. Preparation

Get familiar with the process, drawings, and the positional relationship of the various parts of the product, clean up all the rust-proof oil, dust, chips, and other dirt on the surface of all parts to prevent scratches and damage to the surface during assembly. Moreover, the main matching dimensions (such as an inner hole and journal) should be reexamined, and the parts should be assembled after passing the test.

1.2. Assemble gear shaft components

When the shaft and gear fit are transitional fits, there is a small amount of interference. If the interference is not significant, use a tool (such as a copper rod) to tap and install it. When the interference is significant, a press can be used to press fit. For gears with substantial interference, the assembly method of hydraulic fitting or hot fitting is required. After the shaft and gear are assembled, ensure that the gear is close to the shaft shoulder, at least, 0.03–0.05 m.

1.3. Assembly of the bearing on the gear shaft

When the assembled bearing is a special bearing, such as ZHAOWEI or other brand bearings, the axial clearance is related to the size and surplus of the inner hole. The bearing clearance can be adjusted per the method described later. All bearings must be assembled close to the shaft shoulder or distance ring. The clearance is <0.02. The width of the oil inlet groove and the size of the oil hole of the ball bearing and double row bearing ring should be confirmed before assembly.

1.4. Leveling the gearbox body

Before the assembled gear shaft parts are hoisted on the box body, the gearbox body should be leveled first, and the box body is in a horizontal state, generally within 0.1mm.

1.5. Install the gear shaft components into the gear motor

Put the gear shaft components into the box, and after installing it on the box, check the clearance of all bearings. After passing the test, check the gear backlash. If it needs to be adjusted, it should be adjusted first. After passing the test, the gear grinding can be carried out.

1.6. Grind gear teeth

Coat the driving gear with a colorant (such as red powder, blue oil) by turning it by hand or rotating the motor at low speed and check the contact area and contact position of the gear. If it is unqualified, it must be ground by the machine. The large gear should be ground as much as possible, and the teeth of the two gears that mesh with each other must not be repaired simultaneously.

1.7. Cleaning

For the ground gears, the gears, casings, bearings and other parts should be thoroughly cleaned with kerosene, especially the bearings should be cleaned with clean gasoline, and then blown with a duct. After hoisting on the box, recheck the bearing clearance and whether the gear backlash has changed.

1.8. Close the box

Before closing the box, focus on whether the piping in the box interferes with the gear, whether the fuel injection position of the fuel pipe is correct, and whether the paint in the box is in place. The box can be closed after being checked and recognized as qualified. When closing the box, first install the taper pin for positioning, and then put the bolts. The bolts should be closed first, and the large bolts should be symmetrically closed from the middle of the box. The bolts should be closed according to the relevant torque requirements

1.9. Test

Before the test, connect the lubrication pump station to make the lubrication pipeline of each lubrication point unblocked, the tooth surface is lubricated, and the motor is turned on, and the speed is rotated from slow speed for a while without abnormality. Then, the speed can be slowly increased until it reaches the test speed. The test run time is generally 4 hours, and the temperature change of each bearing position should be recorded every 30 minutes.

With the instructions above, you may have a basic idea of how to assemble a gearbox. If you do not want to do the troublesome manual work by yourself, you can select a suitable finished gear motor by ZHAOWEI. It provides various gear motors. The diameter is between 3.4 and 38mm. The voltage is <24V, the output power is < 50W, and the output speed is between 5 and 1500rpm. The reduction ratio is between 2 and 2000, and the output torque is between 1gf.cm and 50kgf.cm.