Product Introduction: Low-Noise Gear Motors

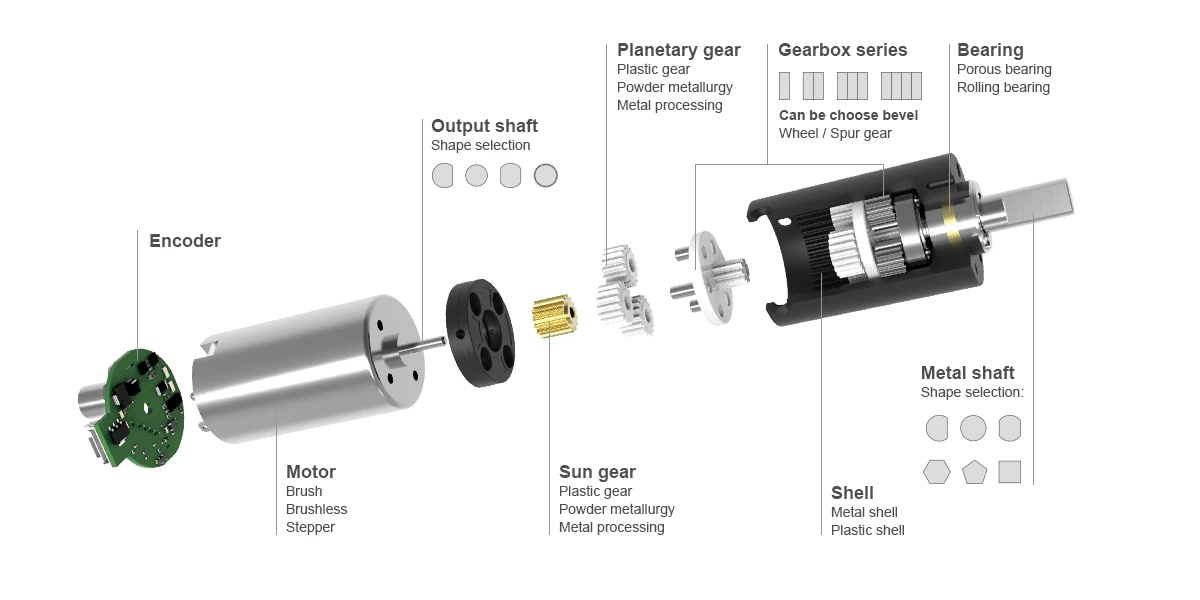

Low-noise gear motors denotes the gear drive equipment whose noise is <45 dB during transmission; these low-noise electric motors are typically a type of micro-drive gear motor with small power. The drive motor can adopt a DC motor, stepper motor, coreless motor, and micro motor as the drive source, while the planetary gearbox can adopt a planetary gearhead, cylindrical gearhead, and worm gearhead as the reducer. ZHAOWEI Drive takes pride in providing gear motors whose noise is <45dB. Low-noise electric motors are extensively used whose technical parameters can be customized by ZHAOWEI based on the applications.

Low-noise electric motors are widely used whose technical parameters can be customized by ZHAOWEI according to the applications. The customizable range includes:

Diameter: 3.4mm-38 mm

Voltage: ﹤24V

Output power: ﹤50W

Output speed: 5-1500rpm

Gear ratio: 2-2000

Output torque: 1.0gf.cm -50kgf.cm

Based on the gearbox structure, low-noise gear motors can be categorized into the coaxial type and two-stage cylindrical type. The micro helical gear motor of the coaxial type has a compact structure, small size, excellent shape, and strong overload capacity. The transmission ratio has fine classification, a broad range of selection, low energy consumption, excellent performance, high efficiency (up to 96%), weak vibration, and low noise. The small gear motor has strong versatility. Besides, it is easy to use and maintain, thereby resulting in low maintenance costs. Moreover, the new type of micro gear motor adopts a new-type sealing device for good protection performance and strong adaptability to the environment to work continuously in corrosive, humid, or other harsh environments. Two-stage cylindrical gear motors are categorized into high-speed gear motors and low-speed gear motors. The high-speed gear reduction motor has better performance when shunted, whereas the gear on the low-speed shaft is arranged symmetrically relative to the bearing and the longitudinal load distribution is even. The radial dimension of the coaxial installation mode of the gear motor is compact, but the axial dimension is large. Meanwhile, owing to the long intermediate axis, the axis bends significantly when it is under load; thus, the load concentration along the tooth width is more serious.

A low-noise gear motor features low noise, small volume, lightweight, high carrying capacity, long service life, stable operation, and high transmission precision. It is extensively used in consumer electronics, intelligent robot, 5G communication device, intelligent logistics, smart cities, smart automobiles, flame-cutting, laser cutting, CNC machine, CNC pipe bender, food packaging, automation industry, aeronautical facility, semiconductor equipment, robot, manipulator, pharmaceutical equipment, printing equipment, packaging machinery, textile machinery, parking equipment, measurement equipment, precision monitoring system, vehicle industry, and automatic control system.