What is a Servo Motor?

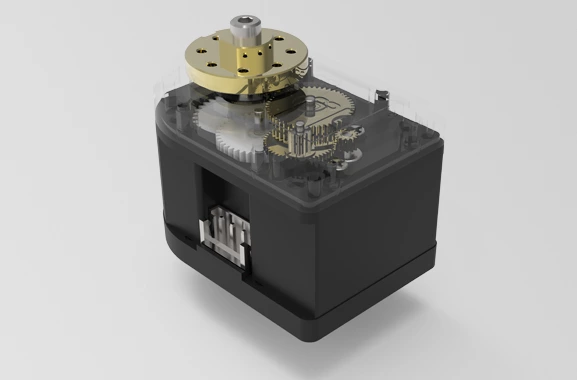

A servo motor consists of a micro motor, a set of reduction gears, a potentiometer (connected to the gear reducer to function as a position sensor), and a controller (generally including a voltage comparator, input signal, and power supply).

How are Servo Motors Different from Stepper Motors?

A servo motor is a system composed of micro motors (usually stepper motors and brushless motors) and various components. When electric pulses are applied to the stator coils, the stepper motor generates a magnetic field to attract the permanent magnet rotor. The error of the servo motor is generally small. Since the power of the micro servo motor comes from the micro motor, there must be a controller that issues commands to the micro motor. The servo motor system should also simultaneously have feedback control.

Principle

The output gear of the servo system’s internal reduction gear set is connected to a potentiometer to form a position sensor. The rotation angle of this servo motor system is therefore affected by the rotation angle of the potentiometer. The two ends of the potentiometer are connected to the positive and negative poles of the power supply, and the sliding end is connected to the rotating shaft. The slider rotates with the shaft, causing the voltage between the potentiometer slider end and the negative end of the power supply to change with the rotation of the shaft. This voltage is the input power supply of the voltage comparator (operation amplifier). The control signal will be sent to the operational amplifier along with the input voltage. The input control signal is a pulse width modulation signal (PWM), and the average voltage changes in proportion to the high voltage in a middle period.

Controlling the Direction of the Micro Motor

First, compare the average voltage of the input signal with the voltage of the power position sensor. If the input voltage is higher than the voltage of the power position sensor, the amplifier outputs a positive power supply voltage. If the input voltage is lower than the position sensor voltage, the amplifier outputs a negative power supply voltage. That is a reverse voltage. In this way, the CW and CCW directions of the micro motor are controlled, and the servo system is controlled by the reduction gear set. If the potentiometer and output gear coupling are not bound, they can be coupled with other shafts of the reduction gear set to control the gear ratio to achieve a larger range of the servo system, including 360° rotation. This may cause greater error, but will not produce cumulative error.

Wide Applications

Servo motors can be applied to various mechanical arms, robots, and automatic doors. There are also special high-torque and high-precision servo motors for fields requiring high accuracy or high torque for a large load. When selecting a model, we need to prioritize torque. How to choose carefully and economically according to the requirements of the servo motor system is also indispensable knowledge, which may require more practice.