Model Selection Guide: Small DC Gear Motors

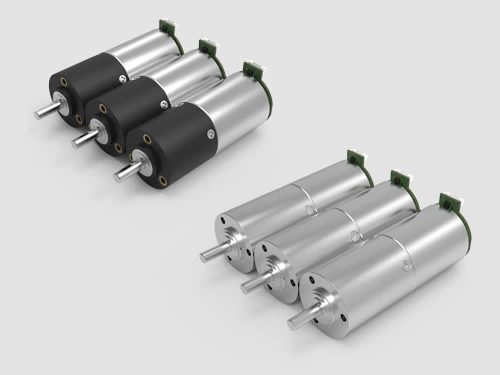

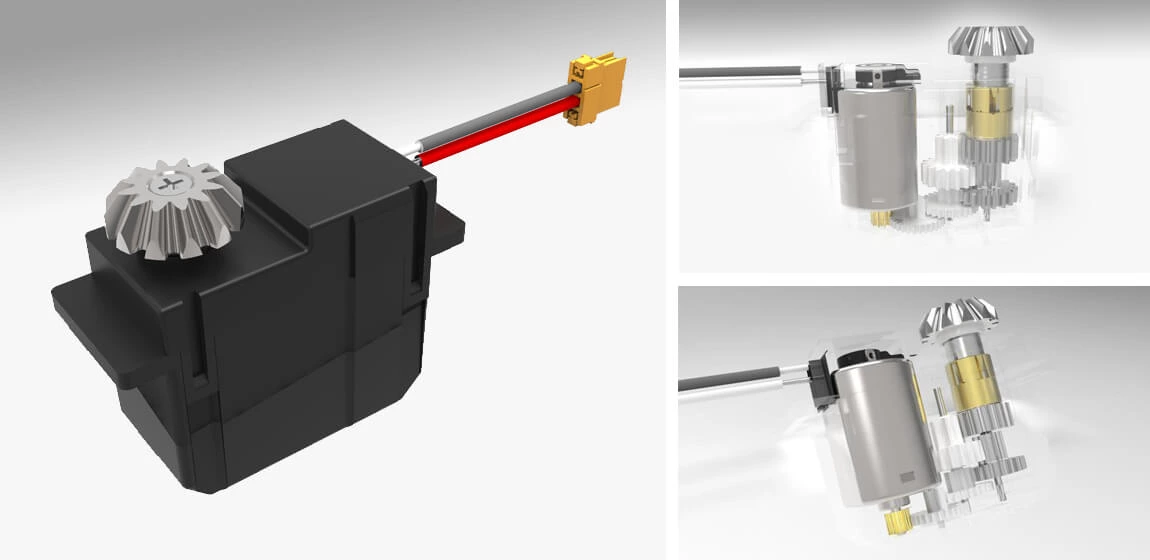

A small DC gear motor is a widely used gear motor. According to the power, it can be divided into high-power and low-power DC gear motors. According to the type of DC motor, it can be divided into brushed DC gear motors and brushless DC gear motors. According to the transmission mode of the gearbox, it can be divided into DC planetary gear motors or DC cylindrical gear motors. Small DC gear motors are widely used in smart homes, automated machinery and equipment, electronic products, and robots.

The technical parameters of DC gear motors applied across industries and equipment are also different. What should be paid attention to when choosing a micro DC gear motor? Here is a DC motor model guide on selection:

- Determine the safety factor (SF);

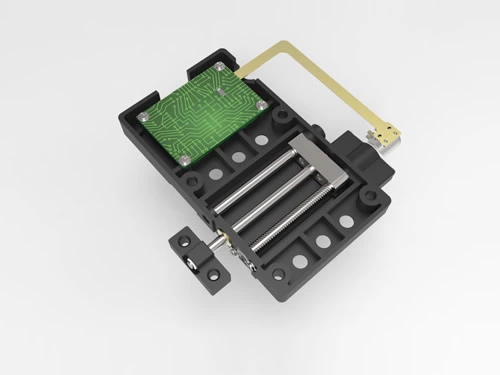

- Installing dimensions of the gear motor;

- Gear ratio of the gear motor;

- Performance parameters of the gear motor, including voltage, power, speed, current, transmission ratio, load capacity, noise, and transmission efficiency;

- Working environment and duty cycle of the motor;

- Calculate the torque of the load. As for the service life of the motor, it is very important to calculate the torque. Pay attention to whether the maximum torque value for acceleration (TP) exceeds the maximum load torque of the motor.

- Determine whether there are any additional functions, such as brake, encoder and frequency conversion.

- Material requirements of the motor.

- Type selection: Gear motors include cage and wire-wound types. The cage type gear motor has a simple structure, easy maintenance, and low price, but poor starting performance. It is often used in production machinery that starts at no load or light load. Wire-wound gear motor has a high starting torque and a small starting current, but its structure is complicated, and it is difficult to start and maintain. It is only used for occasions that require high starting torque, such as lifting equipment. It can also be used for mechanical equipment requiring appropriate speed regulation.

- Power selection: The power selection of the gear motor is determined by the production machinery, that is, by the power required by the load. The motor power required by the gear motor is: Motor Power = Torque ÷ 9550 × Motor Power Input Speed ÷ Speed Ratio ÷ Use Coefficient.

- Speed selection: The speed of the gear motor is close to the synchronous speed, while the magnetic field speed is graded by the logarithm P of the magnetic pole. There is no speed between the two stages. The principle of gear motor selection is to make it as close to the speed of production machinery as possible in order to simplify the rotation device.

- Specification selection: When the power supply and voltage are adjustable, the torque and rotation speed close to the rated value of the product can be selected according to the actual requirements. The required rotation speed can be obtained by changing the voltage. When the power supply and voltage are fixed, if there is no product with a suitable specification, the appropriate specifications can first be selected according to the torque. The voltage and speed of the product can then be adjusted accordingly.

The requirements for selecting a small DC gear motor need to be changed according to your own needs. The parameters of the non-standard DC gear motor can be customized according to the technical parameters.