Gear Motor for Fluorescence Immunoassay Analyzer Parameters

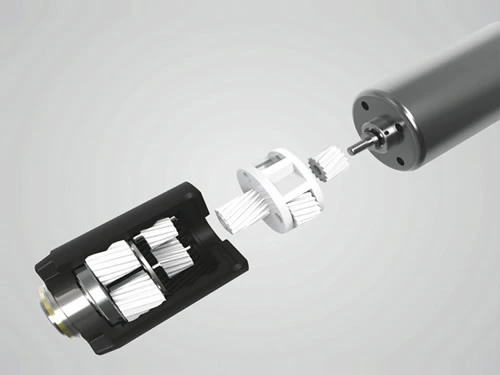

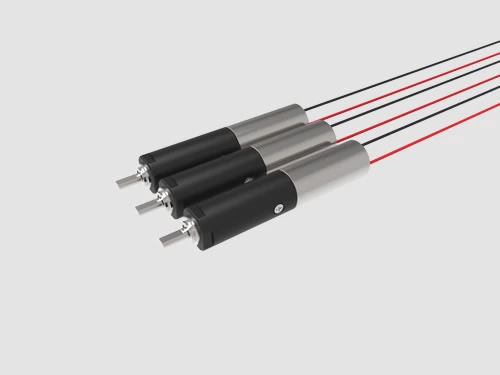

The Fluorescence Immunoassay Analyzer motor is a micro gear motor transmission system used for medical technology. The main transmission structure is composed of drive motor (micro motor) and gearbox (reducer). A brushed DC motor, a brushless DC motor, a stepper motor, a coreless motor, a servo motor can be used as the drive source, and an encoder can also be installed. The planetary gearbox, a plastic gearbox, or a metal gearbox, worm gearbox, parallel-shaft gearbox, cylindrical gearbox can be used as the reducer. There are single-stage, two-stage, three-stage, four-stage planetary gearbox to choose from. The parameters of the planetary gearbox can be developed and customized according to the specific needs. The parameters for immunoassay equipment motor customization are: diameter: 3.4mm-38mm, voltage: under 24V, output power: under 50W, output speed: 5rpm-2000rpm, speed ratio: 5-1500. Output torque: 1.0 gf.cm -50kgf.cm. The gearbox rotation accuracy is 1-2 arc minutes, and the gear transmission noise is below 45dB. ZHAOWEI Machinery & Electronics Co., Ltd is committed to providing a comprehensive customization service.

Parameters of Immunology Analyzer Machine Motor:

| Material | Metal |

|---|---|

| Outer diameter | 12mm |

| Operating temperature | -20℃~+85℃ |

| Direction of rotation | cw&ccw |

| Gear backlash | ≤3° |

| Voltage (Optional) | 3V~24V |

| Bearing | Porous bearing/Rolling bearing |

| Input speed | ≤30000rpm |

| Axial endplay | ≤0.3mm/≤0.2mm |

| Current | 150mA max |

| Radial load on output shaft | ≤0.8N/≤0.5N |

| Motors (Optional) | Stepper/DC/Coreless Motor |

Customization

Project Name: Surgical Stapler

Project Description: ZHAOWEI is committed to the development of micro gear motors. The transmission module of the linear cutting stapler gear motor developed by ZHAOWEI can achieve high torque of surgical instruments in a limited space and reduce the noise problem during use. Based the research on the structure of the stapler, the material of the gearbox and the optimization of gears can contribute to better product performance.