Robot Gear Motor Parameters

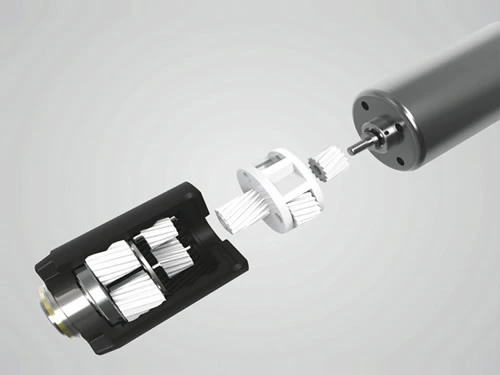

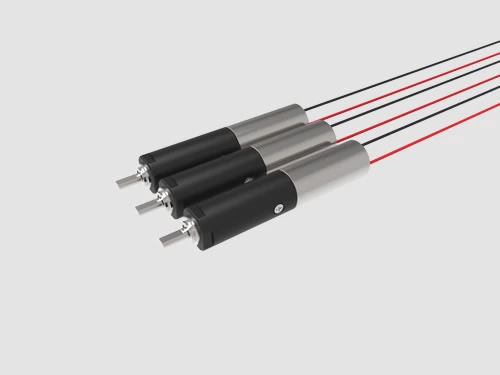

The robot gear motor is the combination of gearbox and a mini robot motor used for the intelligent robot. It’s a reduction transmission system consisting of drive motor (micro motor) and gearbox (reducer). The mini robot motor has the function of deceleration and increasing the robot motor torque, which can enable the robot to move and walk. For example, a DC brushed motor, a servo motor, a stepper motor can be used as the drive source, and an encoder can also be installed. The planetary gearbox, a plastic gearbox, or a metal gearbox, worm gearbox, parallel-shaft gearbox, cylindrical gearbox can be used as a reducer. Parameters, such as output power, output speed, reduction ratio, output torque, rated voltage, diameters, gearbox structure, transmission noise, transmission accuracy, operating temperature are custom-developed. ZHAOWEI Machinery & Electronics Co., Ltd is committed to providing gear motor development and manufacturing drive systems for intelligent robot with customized technical parameters (diameter: 3.4mm-38mm, voltage: under 24V, output power: under 50W, output speed: 5rpm-2000rpm, gear ratio: 5-1500). Output torque: 1.0 gf.cm -50kgf.cm. The gearbox backlash is within 1-2 arc minutes, and the gear transmission noise is below 45dB.

Parameters of Robot Gear Motor:

| Material | Metal |

|---|---|

| Outer diameter | 38mm |

| Operating temperature | -30℃~+100℃ |

| Direction of rotation | cw&ccw |

| Gear backlash | ≤2° |

| Voltage (Optional) | 3V~24V |

| Bearing | Porous bearing/Rolling bearing |

| Input speed | ≤15000rpm |

| Axial endplay | ≤0.1mm/≤0.1mm |

| Current | 300mA max |

| Radial load on output shaft | ≤120N/≤180N |

| Motors (Optional) | Stepper/DC/Servo Motor |

Customization

Project Name: Robot Wheel Motor

Project Background: Robots are divided into wheel type, leg type, crawler type, snake type and compound type according to the movement mode. Among them, wheeled robots occupy a relatively important position in the field of autonomous mobile robots. They have the characteristics of fast motion and simple control and are widely used in automatic palletizing production lines, unmanned vehicles and other fields.

Technical Achievement: The driving part of the wheeled robot adopts a combination of a DC motor and a 38mm planetary gearbox with the anti-symmetric installation method. (Stepper motor for robot wheels is a common type as well.) This method can reduce the force of the output shaft of the reducer, greatly shorten the wheelbase, and save space under the condition that the wheel set is coaxial and great power is needed (Generally the motor size and power is in a certain proportion). In this way, the robot wheel motor can be small in size.