Shelf Motor Parameters

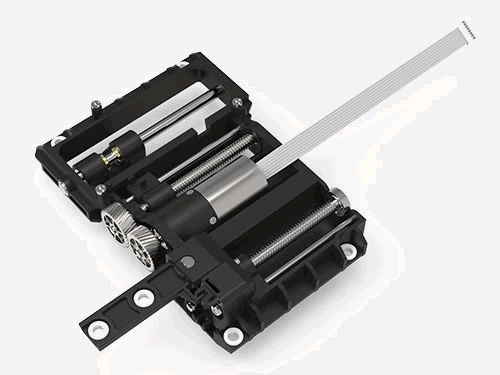

The bookshelf is one of the main pieces of furniture in the study room to store books, newspapers, magazines and other books. The traditional bookshelf has a dull structure and a single function. If the height of the bookshelf is too high, a ladder is needed, which is not convenient to use. A smart shelf motor is a transmission motor used for motorized shelf lift. It has the functions of deceleration, transmission, and improving torque. The main transmission structure is assembled by the drive motor (micro motor) and gearbox (reducer). The technical parameters, specifications, and performance of the gearboxes for motorized shelf system used in different models and scenarios are different

In order to better meet market needs, custom technical parameter development services are generally used. For example, a brushed DC motor, a DC brushless motor, a stepper motor, a coreless motor, a servo motor can be used as the drive source, and an encoder can also be installed. The planetary gearbox, a plastic gearbox, or a metal gearbox, worm gearbox, parallel-shaft gearbox, cylindrical gearbox can be used as the reducer. Parameters, such as output power, output speed, reduction ratio, output torque, rated voltage, diameters, gearbox structure, transmission noise, transmission accuracy, working temperature can be tailor-made.

ZHAOWEI Machinery & Electronics Co., Ltd manufactures gear motors for motorized shelf lift with customized technical parameters including diameter: 3.4mm-38mm, voltage: under 24V, output power: under 50W, output speed: 5rpm-2000rpm, speed ratio: 5-1500, and output torque: 1.0 gf.cm -50kgf.cm. The gearbox rotation accuracy is 1-2 arc minutes, and the gear transmission noise is below 45dB.

Parameters of Shelf Motor:

| Material | Plastic |

|---|---|

| Outer diameter | 22mm |

| Operating temperature | -20℃~+85℃ |

| Direction of rotation | cw&ccw |

| Gear backlash | ≤3° |

| Voltage (Optional) | 3V~24V |

| Bearing | Porous bearing/Rolling bearing |

| Input speed | ≤15000rpm |

| Axial endplay | ≤0.1mm/≤0.1mm |

| Current | 300mA max |

| Radial load on output shaft | ≤5N/≤10N |

| Motors (Optional) | Stepper/DC/Coreless Motor |

Outer diameterOperating temperatureDirection of rotationGear backlashVoltage (Optional)BearingInput speedAxial endplayCurrentRadial load on output shaftMotors (Optional)

Customization of Gear Motor for Motorized Shelf System

Project Name: Gear Motor for Intelligent Standing Desk

Project Background: The emergence of lift desk has well fulfilled the multi-functional requirements, and the conversion between standing and sitting can be realized by pressing a button. At present, there are many intelligent electric standing tables on the market, but there are still some problems such as insufficient load bearing, too limited switchable gears (lifting range), short service life, high power consumption or loud noise during lifting. Sometimes, if the speed is not well controlled, there will be stuck.

Project Introduction: Through the analysis of the usage status of electric furniture users and the current market analysis of office furniture, a smart lifting gear system was developed combined with ergonomics and the current office environment design.

Achievement: ZHAOWEI intelligent lifting gearbox is installed in the lifting column, and can realize adjustment by a customized special-shaped motor with planetary gearbox. It can meet the requirements of small volume and high torque. The gearbox has two-stage, three-stage, and four-stage transmission adjustments available. The reduction ratio, input speed and torque of the gearbox can be changed according to the design requirements of the starting motor of the lifting column. After the information is given, the correctness can be verified by the control system. Then the corresponding feedback is given, and the motor starts. The motor combines with ZHAOWEI gearbox for the intelligent lift desk to realize the stable lifting at even speed and avoid stuck.