Dispensing Valve Motor Parameters

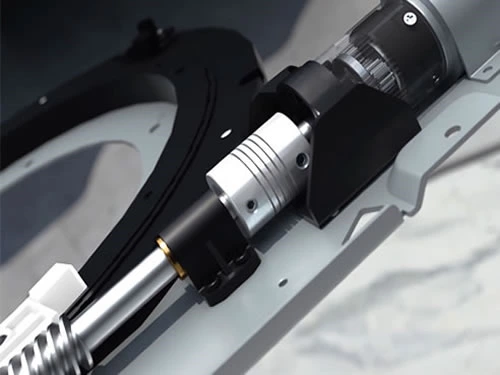

The dispensing valve is an important accessory that determines the flow of glue and is the control port between the glue and the product. A motorized valve can help the operator control the speed and amount of glue accurately. The dispensing valve is composed of an air cylinder, a valve body, and a feed cylinder which is connected up and down. The air cylinder and the valve body are separated by good sealing materials to prevent the glue from invading the air cylinder. The feed cylinder and the air cylinder are connected to the main body of the dispensing valve and are concentric with the air cylinder. The motorized valve actuator is used to drive the air cylinder, then the center rod is driven to move upwards and downwards. And the up and down motion of the center rod is used to open and close the glue flow.

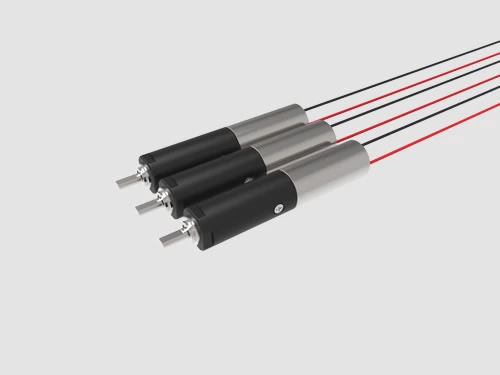

A gear motor for dispensing valve is a gear motor used for the reduction and transmission of dispensing equipment. Generally, the valve motor is a micro gear motor with an output torque under 50W and voltage under 24V. The main transmission is made up of a drive motor (micro motor), and a gearbox (reducer). A DC brushed motor, a DC brushless motor, a stepper motor, a coreless motor, a servo motor can be used as the drive source, and an encoder can also be installed. The planetary gearbox, a plastic gearbox, or a metal gearbox, worm gearbox, parallel-shaft gearbox, the cylindrical gearbox can be used as the reducer. Parameters, such as output power, output speed, reduction ratio, output torque, rated voltage, diameters, gearbox structure, transmission noise, transmission precision, operating temperature is custom-developed. ZHAOWEI is committed to manufacturing and providing gear motors.

Parameters of Dispensing Valve Motor:

| Material | Metal |

|---|---|

| Outer diameter | 12mm |

| Operating temperature | -20℃~+85℃ |

| Direction of rotation | cw&ccw |

| Gear backlash | ≤3° |

| Voltage (Optional) | 3V~24V |

| Bearing | Porous bearing/Rolling bearing |

| Input speed | ≤30000rpm |

| Axial endplay | ≤0.3mm/≤0.2mm |

| Current | 250mA max |

| Radial load on output shaft | ≤10N/≤20N |

| Motors (Optional) | Stepper/DC/Servo Motor |

Customization

Project: Gear Motor for Auto Reclosing

Project Background: In most cases, circuit faults (such as caused by lightning strikes, wind damage, etc.) are temporary. After the circuit breaks, the insulation performance (insulators and air gaps) of the circuit can be restored, and the circuit recloser can succeed.

Achievement: The gear drive system of automatic reclosing (miniature circuit breaker) adopts a helical worm gear multi-drive design, adjusts the transmission structure of automatic reclosing, optimizes its service life and performance, and realizes the switching and closing of the intelligent circuit breaker.

Technical Support: The intelligent reclosing device (circuit breaker gear motor) is used as the effective anti-accident measures on overhead transmission lines and overhead power lines, except for the process of cable transmission and power supply. That’s to say when a circuit fault occurs and relay protection causes the circuit breaker to trip, the automatic reclosing device makes the circuit breaker close again after a short-time-interval, thus improving the reliability of power supply in the power system.