Types of DC Motors – Characteristics & Applications

In today’s industrial sector, direct current (DC) motors are ubiquitous. From robots to cars, small to medium-sized car applications often use DC motors because of their wide range of functionality. Simply put, a DC motor is any type of rotating motor that converts DC electrical energy into mechanical energy. When it comes to the types of DC motors, here are some of the possible ways to classify micro motors.

Since DC motors are deployed in such a wide variety of applications, understanding the different types of DC motors will help you understand which type may suit the tasks in the corresponding application.

Types of DC Motors – Characteristics & Applications

Method One: Classified by Electrical Connections

Generally, DC machines are classified based on the electrical connections of the Armature Winding and the Field Winding. Different types of machines or motors are produced with different types of connections. There are three types of DC Motors. They are:

- Permanent Magnet DC Motors

In permanent magnet DC motors (PMDC), the armature winding is placed in a magnetic field to produce field flux, and it doesn’t contain the field winding. This type of motor uses a permanent magnet to create the magnetic field required for its operation. The advantage of the permanent magnet type is that the rotor does not need power supply, and the rotor structure is reliable. Permanent magnet DC motors have great starting torque capacity with good speed regulation. The steady-state efficiency and power-factor at full load are better than equivalent induction motors in most cases, and they can be synchronized with inertia loads several times the rotor inertia.

PMDC motors are mainly used in cars, including EPB, EPS, windshield wipers, and washers, computer drives, toy industries, smart home such as electric toothbrushes, portable vacuum cleaners, and food mixers.

ZHAOWEI manufactures PMDC motors with precision planetary gearheads. We cooperate with our business partners to develop business and strengthen brand loyalty.

- Separately-Excited DC Motors

In this type of motor, the field winding or coil is powered by a separate or external DC source. The armature winding and the field winding are electrically isolated from each other. The flux produced by the pole depends upon the field current in the unsaturated region of the magnetic material of the pole. i.e., flux is directly proportional to the field current. But in the saturated zone, the flux remains constant. Separately-excited DC motors are often used as actuators in trains and automotive traction applications.

- Self-Excited DC Motors

A self-excited DC motor is a device that the generator itself provides current to the field winding. The field coil can be connected in parallel with the armature, or partly in series and partly in parallel with the armature windings. Self-excited motors are often divided into the following three types:

- Shunt Wound DC Motor (field winding is connected in parallel with the armature)

- Series Wound DC Motor (field winding is connected in series with the armature)

- Compound Wound DC Motor (a hybrid between the series wound and shunt-wound designs)

Self-excited DC motors are often used for lighting purposes and heavy power supply.

Method Two: Classified by Structure

When classified by the structure of DC motors, the two most common types of DC motors are brushed DC and brushless DC (BLDC). Brushed motors were once very common. Although they’ve been largely replaced by their brushless counterparts, applying the correct type of DC motor can make a project more efficient.

Essentially, in a brushed motor, the current is transmitted mechanically via metal brushes, whereas in a brushless motor, the rotor rotates electronically without physical contact.

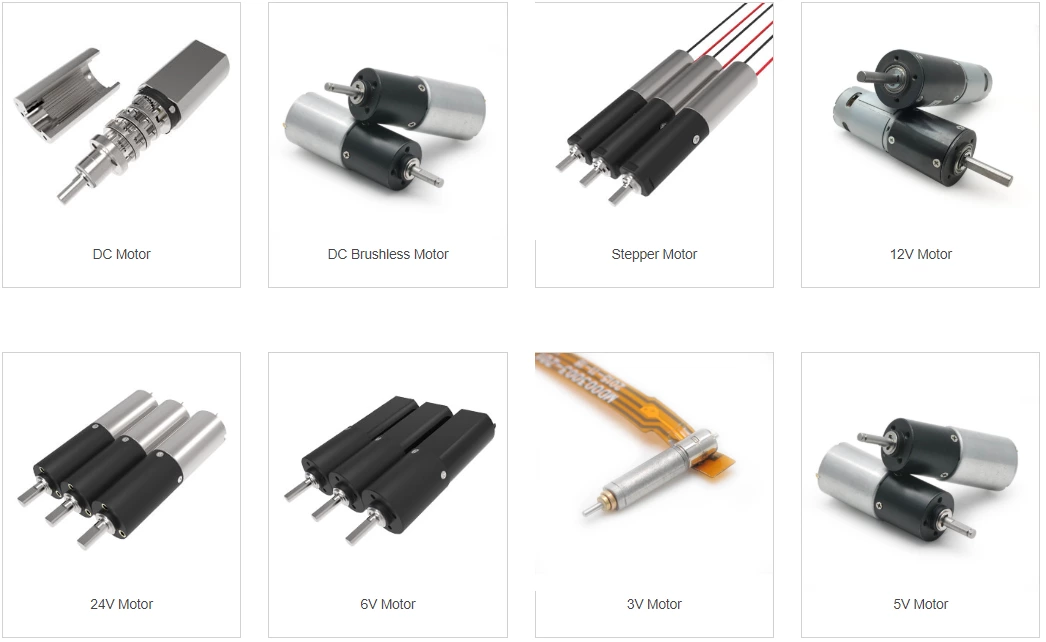

Method Three: Classified by Rated Voltage

According to the rated voltage, micro DC motors can be classified into several types. The most popular types include 3V DC motors, 5V DC motors, 6V DC motors, 12V DC motors, and 24V DC motors. All of these types can be used and customized by the ZHAOWEI drive system. The rated voltage of a DC motor represents the most effective voltage during operation. Be sure to apply the recommended voltage. If the applied voltage is too low, the motor will not work. If the voltage is too high, it can cause the field windings to short-circuit, resulting in power loss or complete damage.

Gears Harness the Power of DC Motors

No matter which type of DC motor you choose, it is vital to understand its application areas. That’s because the issue of DC motors with or without mechanical gears obviously varies between applications. Many devices rely on DC motors for power. Due to their high shaft speed, DC motors are usually paired with micro gearboxes. Take the high torque of a 12V DC motor for example. Without the micro gearbox, its shaft speed often exceeds the requirements of most applications. In such applications where shaft speed must be controlled, using a DC motor alone may not be the ideal option. Therefore, many DC motors are paired with mechanical gearboxes to utilize power.

Conclusion

In summary, this article includes some of the ways to classify DC motors. We hope you’ll have a bit better idea of which type of motor works better for you.