Voltage Affects High Torque Low RPM DC Gear Motor

DC gear motors have various applications in which loads require high torque at low speeds. Each application has specific requirements for speed and torque. The DC motor and gearbox assembly, or high torque DC gear motor, will provide greater performance in an economical solution. In this process, how does the voltage affect high-torque low rpm DC gear motor?

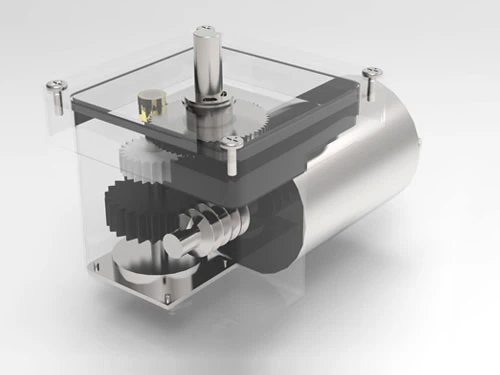

DC Gear Motor Specifications & Characteristics

Several characteristics including input ones and output ones should be taken into consideration when selecting a DC motor.

※ Input Characteristics:

- Voltage

Operating voltage is a fundamental factor and will affect other aspects accordingly. If the battery is the power source of the motor, then a low operating voltage is desirable because fewer batteries are required to obtain the specified voltage. Typical micro DC gear motors often operate at voltages as low as 3V, or as high as 24V. In addition to the 12V gear motors mentioned previously, there are also 24V, 3V, and 6V DC gear motors available on the market. For example, robots often use motors that run on 6V, 12V, or 24V, because most robots are battery-powered, and batteries are typically available within these values. ZHAOWEI has launched a series of micro gear motors, whose voltage can be customized from 3V to 24V.

- Current

The current rating combines with the voltage rating, and the input power can be calculated by multiplying the current by the voltage. The ideal DC gear motor would generate a great deal of power while requiring minimal current. However, the current rating is usually a good indicator of the gear’s power output capacity, and the power input is also a good indicator of the mechanical power output. A given motor simultaneously draws more current when it delivers more output torque. Therefore, current ratings are often given when the motor is stopped. At this point, it is drawing the maximum amount of current and applying maximum torque. Low voltage (e.g., 12V or lower) DC motors may go from 100mA to several amperes when stalling, depending on their design.

※ Output Characteristics:

Then, after affecting the current, how does the voltage affect high-torque low rpm DC gear motors? This is the answer.

- Speed & Torque

Speed is usually specified as revolutions per minute (RPM) when the gear motor is unloaded, or running freely at its specified operating voltage. ZHAOWEI DC motors run at operating speeds of 5 to 2000 rpm. The torque of the motor is directly proportional to the square of the supply voltage. When a gear motor stops, it will produce the maximum torque it can produce. Therefore, the torque rating is usually used when the motor has stalled, this is known as the stall torque. Motor torque is measured in ounce-inches (in the English system) or Newton-meters (metric). The torque of small electric motors is usually expressed in milli-Newton-meters (mN-m) or 1/1000 N-m. ZHAOWEI DC motors operate with an output torque of 1.0 gf.cm to 50kgf.cm. According to the rules, as the voltage decreases, the torque and RPM of the motor will also decrease. It makes no sense to compare the performance of 24V DC gear motors and 3V/6V DC gear motors. They are suitable for different applications, and depend on the speed and torque required.

- Power

The power of a motor is the product of its speed and torque. The power output is greatest at about halfway between the no-load speed (maximum speed, no torque) and the stalled state (maximum torque, no speed). The output power in watts is about (torque) x (rpm) / 9.57.

Selecting the Right Gear Motor

Of course, voltage is not the only factor that affects the gear motors, but it is still an important factor. Micro DC gearmotors have a rated voltage, but these motors can generally run at voltages higher or lower than this nominal voltage within a specific range, so they should be able to operate comfortably. But excessively low, or high voltage may not be practical, which may negatively impact the durability of the gear motor. Therefore, it is important to consider the voltage that can be provided before selecting the appropriate gear motor.

ZHAOWEI offers a wide selection of gear motors with various rated voltage options you require. We offer different combinations of speed and torque. Don’t hesitate to find a gear motor that better meets your project requirements.