What are Gear Motors?

Gear motors are a fairly well-established technology. Recently, there has been renewed interest in gear motors. Due to the increase in power generation from renewable energy sources, and the demand for increased efficiency in the renewable energy sector, the global gear motor market is expected to experience moderate growth during the forecast period. According to the related reports, it is projected to reach USD$23.94 billion by 2021, with a CAGR of 5.8% from 2016 to 2021.

But…what is a gear motor indeed?

-

Definition

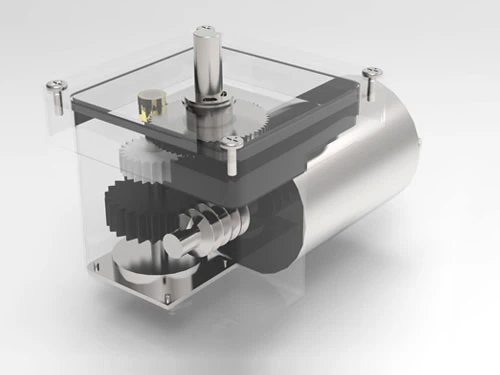

The question of “what is a gear motor” is equivalent to “what is a gear reduction motor”. Essentially, a gear motor is a pairing of a gear reducer and an AC/DC electric motor. Gear motors are basic in design, and uses some combination of plastic and/or metal gears. The gear and motor are combined into one unit, and a gear system is used at the output of the motor. The motor powers the gearbox, turns the box, and generates energy. Together, they work to increase torque (force) while keeping RPM (speed) low. Therefore, one of their greatest benefits is that they do not require a separate gearbox and electric motor. This reduces design complexity, and reduces costs, especially for motors built for high-torque and low-speed applications. In addition, gearboxes can be used as a means to reorient the output shaft in different directions.

-

Types

There are several ways to classify the types of gear motors. Speaking of which, planetary gear motors are a very popular and common type. Planetary gears use several gear wheels (usually three sets of gears with different degrees of freedom) to drive the power of the central shaft of the motor, similar to planets orbiting the sun. Planetary gear motors perform better when high torque is required. Planetary gears are further divided according to optional materials, which can be divided into plastic gears, powder metallurgy, and hardware processing. According to optional gear profiles, they can be divided into helical gears and spur gears.

ZHAOWEI produces its own series of high-performing planetary gears, with a variety of optional material, tooth profile, diameter, output speed, reduction ratio, and output torque to choose from. Micro planetary gear motors can be combined with encoders and controllers to form a micro gear drive system, which is mainly used in smart homes, communication devices, medical technology, robots, and consumer electronics.

Why are Motors with Planetary Gears Often Used?

- Increased torque transmission: With more teeth in contact, the mechanism is able to transmit and withstand more torque, operating in a more uniform manner.

- High precision: Most of the rotation angle stability improves the accuracy and reliability of the movement.

- Lower noise: There is more surface contact. The rolling is much softer, with almost no jumps.

- Enhanced efficiency: Due to its compact design and internal layout, planetary reducers offer enhanced efficiency and minimize losses while operating.

- Greater durability: Due to its torsional rigidity and better rolling performance, the bearing helps to reduce the loss caused by the friction of the shaft directly on the box. Therefore, improving gear efficiency, and smoother operation is achieved.

- Increased repeatability: Its higher speed radial and axial loads provide reliability, and minimize gear misalignment. In addition, uniform transmission and low vibration at different loads make better repeatability possible.

Applications

The purpose of the gear motor is also a vital question related to what a gear reduction motor is. Gear motors are generally used in applications that require lower shaft speed and higher torque output. This describes a wide range of applications and scenarios, including many machines and equipment that we interact with on a daily basis. From automobile window wipers to hospital beds, servo-mechanisms to packaging equipment, paint mixers to soap dispensers, gear motors play a significant role. Main industries include power generation, material handling, food & beverage, metals & mining, cement & aggregates, automotive, construction, chemicals, rubber, plastics, and ships.

Conclusion

After you understand what a gear motor is, please take the time to properly adjust the size of the gear motor without hesitation. This will help you realize that it can be used for years, and operate at maximum efficiency.