What are Planetary Gears?

Planetary gears, also known as planetary gear trains, appears to be quite complicated. In fact, a skilled gear engineer needs to master all the intricate aspects of designing a planetary gear system. If you want to have a more basic understanding of planetary gears, then you have come to the right place.

What are Planetary Gears?

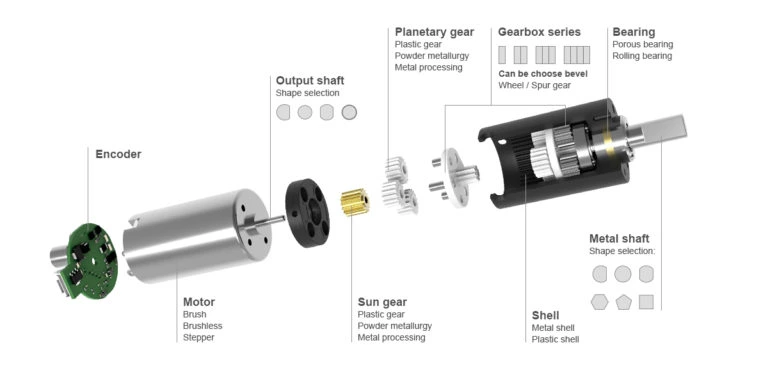

A planetary gear set consists of three types of gears including sun gears, planet gears (also called satellite gears), and ring gears. The sun gear is located in the center and transmits torque to the planet gears, which are usually mounted on a moveable carrier. The strength of the planetary gearhead is usually determined by the size of the sun gear. A larger sun gear will allow a higher torque value. The planet gears orbit the sun gear and meshes with the outer ring gear. Depending on the application, the complexity of planetary gear systems can range from very simple to complex compound systems.

Why is it Called a Planetary Gear?

Planetary gear sets, also called planetary gearheads, are named after how different gears move together. In the planetary gearhead, we see a sun (solar) gear, ring gear, and two or more planet gears. Normally, the sun gear is driven and thus moves the planet gears locked in the planet carrier, forming the output shaft. The ring gear has a fixed position with the outside world. This looks similar to our planetary solar system, which is where the name comes from. In practice, we often talk about the use of planetary gearheads in industrial automation. That is why we refer to the sun gear as the input shaft, the planet gears and planet carrier as the output shaft, and the ring gear as the housing.

What are the Advantages of the Planetary Gear System?

- Coaxial arrangement of the input and output shafts

- Load distribution to several planetary gears

- Many gear ratio options due to the combination of multiple planet stages

- Because the planetary gearbox is fixed, it is suitable as a planetary switching gear

- Favorable low-noise

- Suitability for a wide range of applications

Where are Planetary Gearheads Usually Used (In the Transmission)?

Planetary gear systems can generate the required torque because the load is shared by multiple planet gears. Compared with the traditional parallel axis gear system, this arrangement also creates more contact surfaces, and a larger contact area between the gears. Therefore, the load is more evenly distributed, and the gears are more resistant to damage.

This structure makes the Planetary Gearheads, combined with ZHAOWEI DC micro motors, ideal for high torque, low speed and high-performance applications. In most cases, the gear train of the input stage is made of plastic to keep noise levels as low as possible at a higher RPM. Sometimes, powder metallurgy is also a common technology often used in planetary gearheads. The metal input stage can also be used for extreme loads. The gearhead is mounted to the motor through a threaded flange to provide a solid fit.

Such a combination contributes to a wide range of applications including:

- In robots to increase torque

- In printing presses to reduce roller speed

- For precise positioning

- In packaging machines for reproducible products

Purchasing a Planetary Gearhead: What Should You Pay Attention to?

What is the purchase criteria for planetary gearheads? The answer largely depends on the precise location of the gearhead. First, the primary specifications (e.g.: torque, backlash, ratio) must be correct, but then the secondary (e.g.: corrosion resistance, noise level, structure), and the tertiary (eg.: delivery time, price, global availability, service) specifications are important.

More specifically, here are the main processes that you should pay attention to:

- Choose shaft shape: D-type, round, double flat, hexagon, pentagon, and square. Then, choose suitable bearings, which are usually divided into two types: porous bearing and rolling bearing.

- Choose the materials of the satellite gears and sun gears in micro planetary gearheads. There are plastic gears, powder metallurgy materials, and hardware processing. ZHAOWEI provides metal and plastic housings for micro planetary gearheads, suitable for any application that you need, within reach.

- The single-stage planetary gear cannot satisfy the large planetary gear transmission ratio. Sometimes it needs 2-stage or 3-stage or even 4-stage to meet the requirements of a larger transmission ratio. As the number of planetary gears increases, the load distribution increases, so the torque that can be transmitted increases.

- Choose a suitable motor. ZHAOWEI provides optional motors, such as brushed DC motors, DC brushless motors, stepper motors, and coreless motors, which can be matched with your micro planetary gearhead for better performance.

Note: For more details (voltage, current, gear ratio, diameter torque, etc.), ZHAOWEI also provides you with related information and customized services.