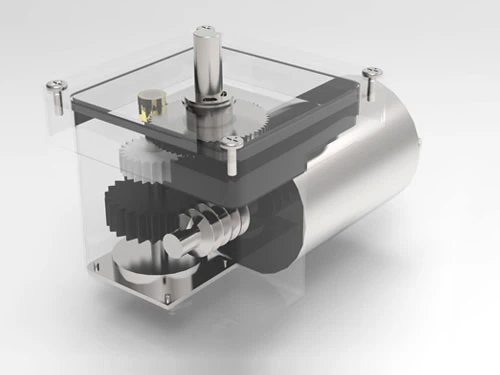

What is the Use Coefficients of Gear Motors?

The use coefficient of the gear motors is also known as the gear motor service factor or safety factor. It is very important and is directly related to whether the gear motor can run safely and smoothly. Therefore, the appropriate gear motor should be selected according to service conditions.

What is the service factor of the motor? The load factor of the gear motor is a vital parameter when calculating the gear motor service factor. It is equal to the load time divided by the total running time. When selecting the type of gear motor, it is necessary to make sure that the use coefficient of gear motor is greater than 1 (generally > 1, namely the capacity of gear motor > motor capacity) according to your service conditions. Daily running time, number of starts times per hour, and ambient temperature are some of the factors that help achieve the surplus of the rated mechanical energy and thermal energy of the gear motor.

The formula for calculating the use coefficient of gear motor:

- Use coefficient =Rated output power/Motor power (to get the use coefficient of the gear motor type with continuous loads)

Calculating train of gears:

- Reduction ratio = Number of driven gear teeth ÷ Number of driving gear teeth (When a gear train has multiple stages, the reduction ratio for the overall gearing system is the product of the individual stages.)

- Motor power = Torque ÷ 9550 × motor power input speed ÷ speed ratio ÷ use coefficient;

The use coefficient in gear motors is a key parameter, and its quality directly determines whether the gear motor can run normally and effectively in the future, so more attention should be paid to the selection.