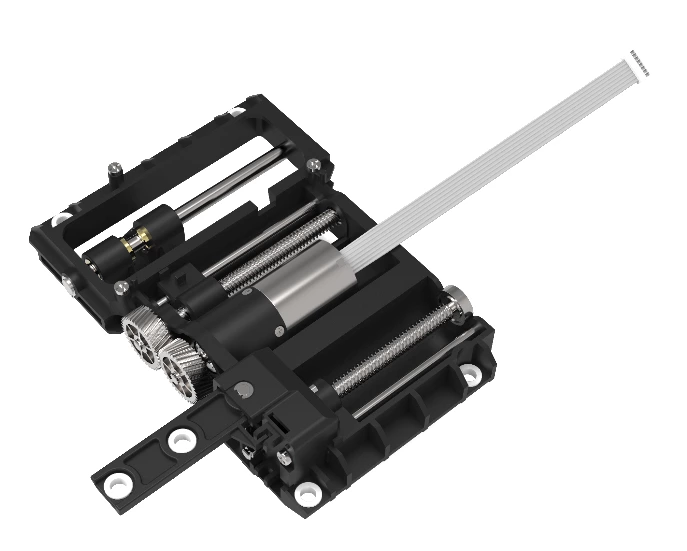

What are DC Gear Motors?

A DC gear motor is the combination of a regular DC motor and a gear reducer. The gear reducer functions to provide low speed and high torque. Gearboxes with different reduction ratios produce different speeds and torques, which improve the utilization rate of DC motors in the automation industry. DC gear motors have high transmission precision, compact size, low-noise, low energy consumption, and long service life.

The Function of DC Gear Motor

On the one hand, the DC gear motor can reduce output speed. The gearbox is combined with the DC motor, and the motor speed can be reduced through the gearbox. On the other hand, the DC gear motor can improve the output torque of the motor and reduce the inertia of the load.

Classifications of DC Gear Motor

According to transmission mode: Gear reduction motors, worm reduction motors, planetary gear motors, gear motors combined with gear and worm reduction.

According to the shape of gear: Cylindrical gear motors, bevel gear motors, and conical cylindrical gear motors.

According to transmission degrees: Single-stage gear motor, multistage gear motors.

According to types of motor: Brushless DC gear motors, brushed DC gear motors, brushless gear motors for massage machines, brushless DC motors.

The Application of DC Gear Motor

DC gear motor are widely used in fields including smart cars, intelligent communication, intelligent logistics, intelligent medical, intelligent city, consumer electronics, personal care tools, industrial automation equipment, smart home, precision instruments and equipment, outdoor exploration equipment, and photographic equipment.

The Parameters of DC Gear Motor Developed by ZHAOWEI:

Diameter: 8 mm -38 mm

Materials: plastic gear and metal gear

Voltage: 3V-24V

Transmission noise: under 45dB

Gear ratio: 5-1500

Output speed: 5-2000 rpm

Output torque: 1 gf.cm-50kgf.cm

Transmission precision: 1-2 arcmin

ZHAOWEI also provides customized services according to our clients’ requirements.