Why Do We Need Gear Motors?

A gear motor is a motor coupled with gear trains. The gear motor usually uses AC (alternating current) or DC (direct current). In most cases, matching with the gearbox aims to limit the speed of the motor shaft and increase the output torque. Gears actually convert the shaft speed to torque at a specific ratio, with minimal efficiency loss. By adding a gearbox of appropriate size and configuration, ideal torque output and speed can be realized.

Per the volume, gear motors can be categorized into large gear reducer motors, medium gear reducer motors, and small gear reducer motors. Many devices use gear motors to decrease speed, increase torque, and change the rotation direction. Large and medium gear motors can be used in packaging machinery, conveyor machinery, food machinery, color box machinery, automatic storage, three-dimensional warehouse, three-dimensional parking lot equipment, textile, chemical, and other equipment.

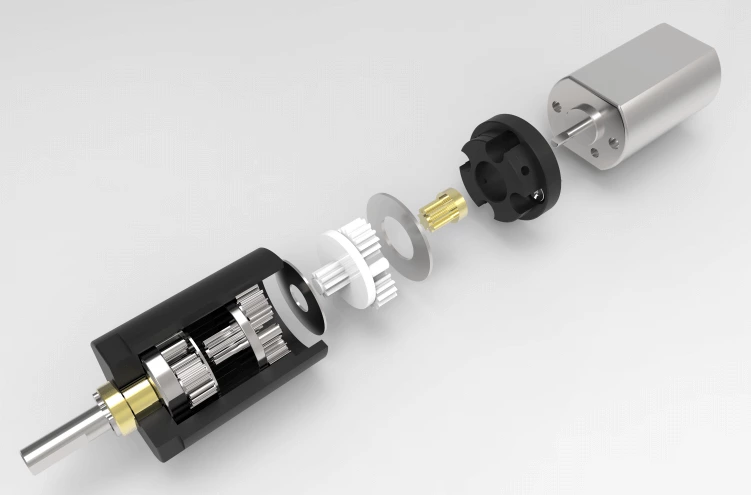

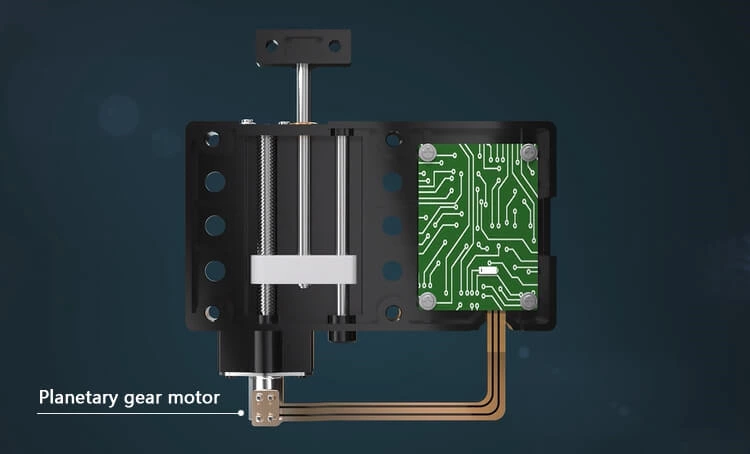

The small gear motor comprises gears and a micro motor, which has high precision, compact size, low noise, and smooth operation. ZHAOWEI can provide micro planetary gear motors, which are small. The micro planetary gear motor can be combined with encoders and controllers to form micro gear drive systems, primarily used in smart homes, communication technology, medical technology, robots, and consumer electronics. The micro gear motor plays a vital role in these areas.