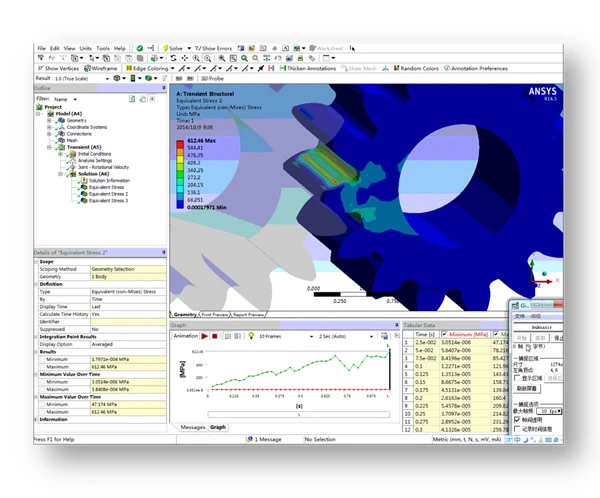

Tooling design of gear is different from traditional mold design,it need actual experience data to adjust the gear tooth thickness, modulus, pressure angle, also the tooling manufacture can not based on the theory shrinkage rate of material directly, our advantages are:

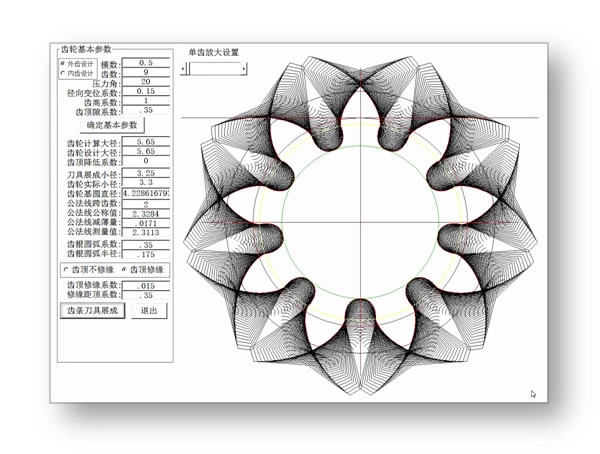

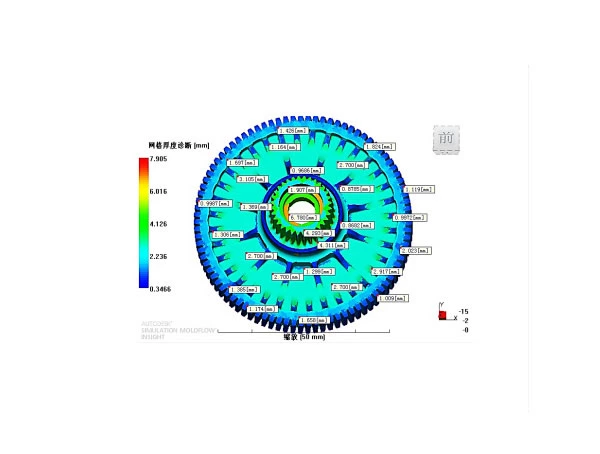

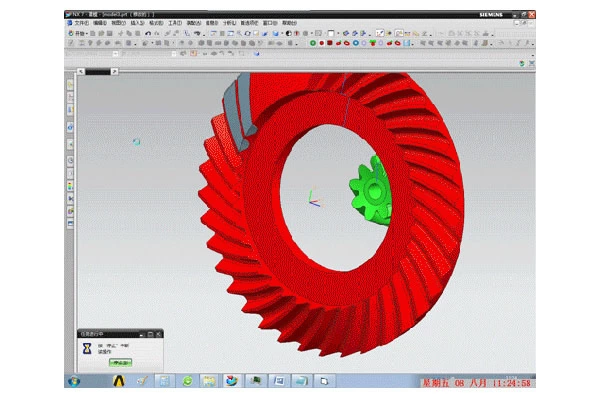

On the basis of KISSSOFT, we independently developed the parametric calculation software of plastic gear mold cavity according to our working experience. The software can create the model of gear profile and modify the gear shape to enhance the pricision of gear profile .

After the gear model created by the software , it can be used to machine manufucture by the wire cutting and EDM , so that the precision of tooling fabrication is enhanced.