ZHAOWEI micro drive system can be applied to clean the sediments and residues quickly without damaging the heater, which not only significantly reduces the tim...

Gear Motor for Logistics Cameras

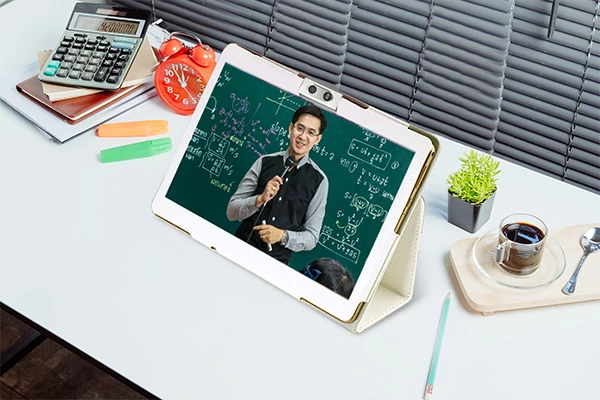

Despite the rapid development of e-commerce, logistics and distribution have always been the bottleneck of e-commerce development. Imperfect distribution systems, high logistics costs, poor service quality, low efficiency, and small distribution scopes greatly hinder the development of e-commerce. Improving the efficiency of distribution centers, which are the foundation of the logistics supply chain, is always a key task for logistic companies. It’s for this reason that, intelligent technology has become the development trend of the logistics industry. ZHAOWEI has made contributions to this industry as well, by combining the Internet of Things (IoT) with gear motors for security alarm sensors and cameras to help monitor theft and protect goods.

With intelligent technology, logistics companies can achieve remote control of locking doors, receiving alerts, and monitor in real time. The data they receive can be collected and analyzed to improve shortcomings.

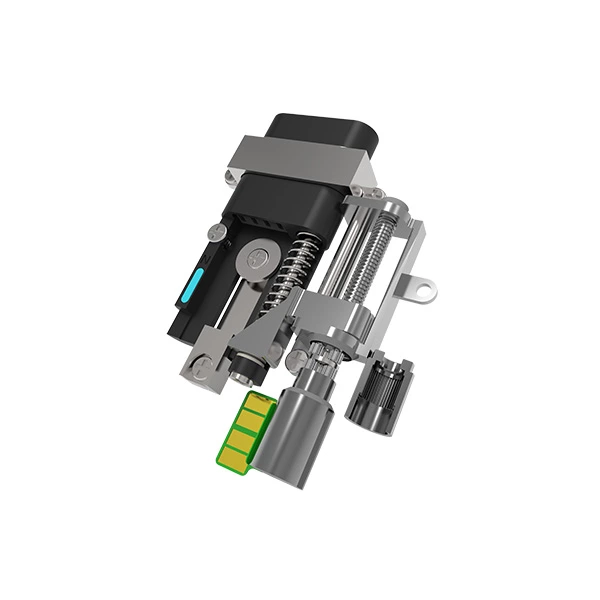

Logistics cameras are generally small. For this reason, gear motors for logistics cameras need to fit in a limited space. This means that they require both a compact size and a high torque. The ZHAOWEI gear motor for logistics cameras uses an 8mm planetary gear motor. To meet different torque requirements of the camera at different angles and positions, ZHAOWEI has designed a multi-layer variable transmission structure. The specific requirements for consumers for transmission ratios and torque can be met by selecting 2-stage, 3-stages, and 4-stages gearboxes. Flipping the camera in all vision systems, flipping the side camera, screwing out the camera at the top of the machine, and stretching and retracting the camera can be achieved.

Low Noise

ZHAOWEI adopted a comprehensive design platform in the early stage of development and design, achieving automatic structure design, including an involute planetary gear system, bevel gear, and face gear. By optimizing gear parameters like the modification coefficient, tooth coefficient, pressure angle, and center distance, ZHAOWEI has reduced the impact speed of meshing and limits the ratio of meshing-in impact speed to the meshing-out impact speed in a certain range. With these measures taken, the noise during use is reduced.

ZHAOWEI has made optimizations in service life and product quality. During the design stage, ZHAOWEI uses kinematics simulation to verify the smoothness and local interference of the gear pairs. At the same time, finite element analysis technology is used to analyze and check the tooth surface strength of spiral teeth and bevel gears. Cavity pressure technology is used to detect changes in cavity pressure during injection molding and monitor product quality.

ZHAOWEI gear motors for the cameras come in various models, including gear motors for rotating phone cameras, stepper motors for the pop-up cameras, drive systems for conference video systems, gear motors for auto-focus cameras, and more.

In addition to logistics cameras , we also provide solutions for E-cigarettes cleaning, rollable screen phone, water flosser, lifting camera, full-screen phone camera, learning tablets camera, earbuds charging case, dome camera, concealed E-cigarette, dishwasher, automatic litter box, coffee makers with grinder, intelligent lift socket, portable photo printer, smart bike lock, electric screwdriver, smart lockers for packages, anti-myopia smart pen and smart mouse.