The development of the dental handpiece was one of the most significant innovations in dentistry. As a necessary medical dental tool, it is continuous upgrading...

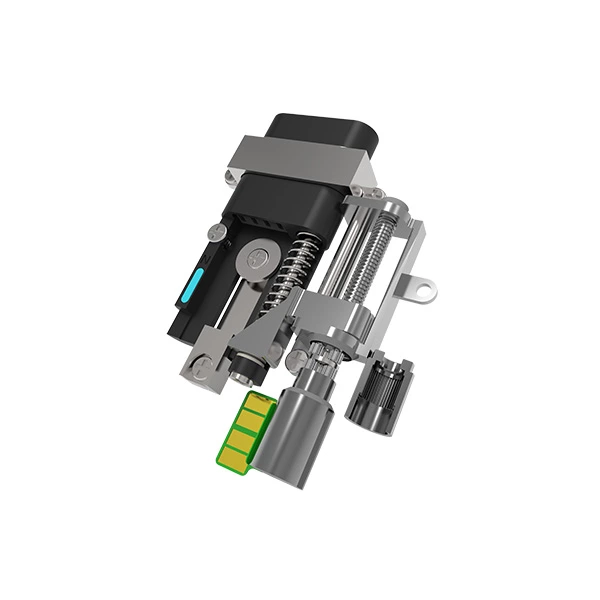

Facial Cleansing Brush Gearbox

Some facial cleansing brushes use magnetic levitation vibration to drive the metal piece in front of the magnet to resonate. Others use electric motors. Both methods are used to cleanse faces through vibration. The main structure of this kind of facial cleansing brush consists of motors, circuit boards, and rechargeable batteries.

The ZHAOWEI micro-drive system can be used with intelligent facial cleansing brushes. Through vibration and friction, the cleansing product will be emulsified and combined with dirt on the skin. For smart facial cleansing brushes, a compact size may result in insufficient torque to effectively clean faces, while the complex structure may lead to an increase in size or torque that is too high, which is not suitable for daily use and can easily cause damage to the surface of the skin. A good facial cleansing brush should be able to remove makeup and clean the skin without causing any harm.

Optional Multistage Transmission

The ZHAOWEI 16MM planetary gearbox can be used with intelligent facial cleansing brushes to achieve forward and reverse adjustment of the machine. The gearbox structure has two-stage, three-stage, and four-stage transmission changes to choose from. The reduction ratio, output speed, and torque can be selected based on your specific needs.

Reduce Noise

In addition to providing stable and moderate washing force, cutting down on buzzing noise during use is not something to be looked over. The gears in the planetary gearbox for facial cleansing brushes use noise-reducing materials and self-lubricate, which effectively reduces noise. Even if the facial cleansing brush is of excellent quality, it will lose its competitiveness if the transmission gear has a short service life.

Improve Quality

To improve the service life and quality of the product, ZHAOWEI has used kinematics simulation to verify the smoothness and local interference of the gear pairs during the gearbox design stage. In addition, finite element analysis technology is adopted to analyze and check the tooth surface strength of spiral teeth and bevel gears. Cavity pressure technology is used to detect changes in cavity pressure during injection molding and monitor product quality.

Facial Cleansing Brush Gear Motor

Planetary Gearbox for Facial Cleansing Brush