The important application of micro drive system in humanoid robot

The important applications of micro transmission systems in humanoid robots are mainly reflected in the following aspects, especially the micro transmission mechanism provided by ZW Drive, which provides key technical support for humanoid robots in multiple aspects.

1. Joint drive

Micro transmission systems are used to drive the joints of humanoid robots, such as elbows, knees, and wrists. These systems provide the precise control and torque required to enable robots to achieve smooth and precise movements, mimicking human actions.

2. Agile operation

In the hands and fingers of humanoid robots, micro transmission systems enable subtle and precise movements. This enables robots to perform tasks that require high flexibility, such as picking up small objects, typing, or using tools.

3. Facial expressions

The micro transmission system is used to control the facial muscles of humanoid robots, enabling them to display various expressions. This is crucial for designing robots for social or service environments, as it enhances communication and resonance with humans.

4. Balance and Movement

The micro transmission system plays a crucial role in balance and motion. They help control the movement of the legs and feet, ensuring stability and enabling the robot to walk, run, and even climb stairs. This requires precise coordination and real-time adjustment to maintain balance.

5. Compact and lightweight design

The compact and lightweight characteristics of micro transmission systems make them highly suitable for integration into humanoid robots, which have strict requirements for space and weight. This makes robots more agile and responsive.

6. Energy efficiency

The design of micro transmission systems emphasizes energy efficiency, which is crucial for humanoid robots that require long-term operation without charging. The efficient driving system reduces overall energy consumption and extends the operation time of the robot.

7. High precision and reliability

Humanoid robots require high-precision and reliable motion. Micro transmission systems provide the required precision and consistent performance, which is crucial for tasks that require repeatability and meticulous control.

8. Integration with sensors and control systems

Micro transmission systems can be integrated with various sensors and control systems to achieve real-time feedback and adaptive control. This integration enhances the robot's ability to interact with the environment, enabling it to autonomously perform complex tasks.

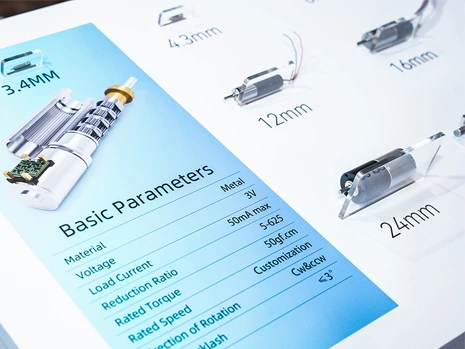

Application examples of ZW Driver

·Facial expression control: Through a micro transmission system, the facial expression control of humanoid robots can be achieved, enabling them to express diverse emotions and reactions.

·Hand movements: The micro transmission system enables robots to perform complex hand movements such as grasping, handling, and fine manipulation.

·Walking and Running: The micro transmission mechanism ensures that the robot can walk and run smoothly, adapting to different terrains and environments.

The micro transmission system provided by ZW Drive plays a crucial role in these applications, providing solid technical support and innovative momentum for the development of humanoid robots.