12 mm High Performance Planetary Gearbox

Model: ZWSMD012012

Gearbox Specifications: Bearing Porous bearing Axial Endplay ≤ 0.3 mm Radial Loading on Output Shaft ≤ 5 N Operating Temperature -20℃ ~ +85℃ Parameters: Gearbox Stages 1 2 3 4

- Diameter

- 12 mm

- Voltage Range

- 12 V

- Reduction Ratio

- 16-1526:1

- Max. Transmittable Power

- 2.2 W

- Max. Continuous Torque

- 0.35 Nm

- Max. Continuous Input Speed

- 16000 rpm

- Bearing at Output

- Ball bearing

- Max. efficiency (%)

- 55-75

- Rated Speed Range

- 18-1284 rpm

- Operating Temperature

- -40…+100℃

Parameters:

| Gearbox Stages | 2 | 3 | 4 |

|---|---|---|---|

| MAX. Continuous output torque (Nm) | 0.25 | 0.3 | 0.35 |

| MAX. Instant mobilization torque (Nm) | 0.3 | 0.38 | 0.41 |

| Reduction ratio | 16,21,26,28,35 | 62,83,103,111,138,150,172,186,231 | 243,326,406,439,546,590,679,734,794,913,987,1135,1227,1526 |

| Outer diameter (mm) | φ12 | ||

| Gearbox length(mm) | 17.5 | 23.3 | 27.8 |

| Maximum efficiency(%) | 75 | 65 | 55 |

| Recommended temperature range(℃) | -40~+100 | ||

| MAX. Gearbox weight (G) | 12.4 | 15.5 | 18.6 |

| Maximum transmission power (continuous)(W) | 2.2 | 1.1 | 0.6 |

| Maximum transmission power(instantaneous)(W) | 2.8 | 1.4 | 0.8 |

| Air load average empty return (°) | 1.5 | 1.8 | 2.1 |

| The maximum axial load (dynamic)(N) | 20 | 20 | 20 |

| The maximum radial load (4mm from France)(N) | 45 | 60 | 60 |

| Output Bearing | Ball bearing | ||

| Axial gap(mm) | < 0.1 | ||

*Note: The above data does not include the motor, the overall sale of the deceased and the motor, the specific parameters can be customized according to the customer's requirements.

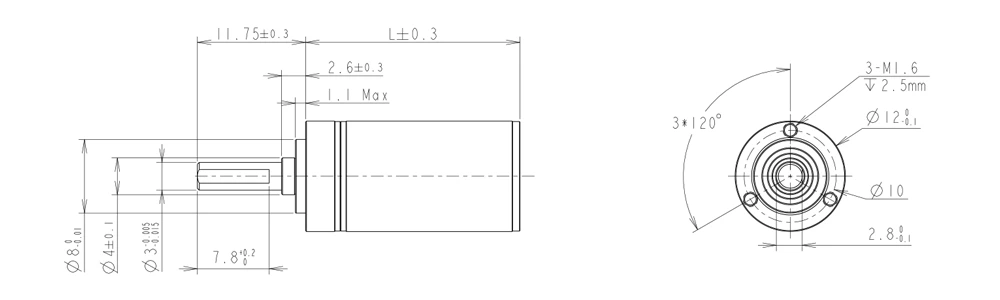

Drawing:

Modular Assembly:

| Combined product | Model | Series | |

|---|---|---|---|

| dc motor | 1220 Φ12 mm coreless metal brush motor | 2-4 | |

| dc motor | 1228 Φ12 mm coreless metal brush motor | 2-4 | |

| brushless motor | 1226 Φ12 mm coreless metal brush motor | 2-4 | |

| brushless motor | 1232 Φ12 mm coreless metal brush motor | 2-4 | |

| encoder | CB-ST-12 | Magnetic | |

Performance Data:

| Model | Rated voltage | Air load data | Load data | Total length | Gearbox rated torque | Gearbox instantaneous torque |

Reduction ratio |

Gearbox length L1 |

|||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Air -load speed | No-load current | Load speed | Load current | Torque | |||||||

| (V) | (rpm) | (mAmax) | (rpm) | (AMax) | (NM) | (mm) | (NM) | (NM) | / | (mm) | |

| ZWSMD012012-16-X | 12 | 1836 | 117 | 1284 | 1 | 0.034 | 43.5 | 0.25 | 0.3 | 16 | 17.5 |

| ZWSMD012012-21-X | 12 | 1365 | 117 | 955 | 1 | 0.042 | 21 | ||||

| ZWSMD012012-26-X | 12 | 1098 | 117 | 768 | 1 | 0.052 | 26 | ||||

| ZWSMD012012-28-X | 12 | 1015 | 117 | 710 | 1 | 0.056 | 28 | ||||

| ZWSMD012012-35-X | 12 | 816 | 117 | 571 | 1 | 0.070 | 35 | ||||

| ZWSMD012012-62-X | 12 | 465 | 117 | 325 | 1 | 0.100 | 49.3 | 0.3 | 0.38 | 62 | 23.3 |

| ZWSMD012012-83-X | 12 | 346 | 117 | 242 | 1 | 0.134 | 83 | ||||

| ZWSMD012012-103-X | 12 | 278 | 117 | 195 | 1 | 0.167 | 103 | ||||

| ZWSMD012012-111-X | 12 | 257 | 117 | 180 | 1 | 0.181 | 111 | ||||

| ZWSMD012012-138-X | 12 | 207 | 117 | 145 | 1 | 0.225 | 138 | ||||

| ZWSMD012012-150-X | 12 | 191 | 117 | 134 | 1 | 0.243 | 150 | ||||

| ZWSMD012012-172-X | 12 | 166 | 117 | 116 | 1 | 0.279 | 172 | ||||

| ZWSMD012012-186-X | 12 | 154 | 117 | 108 | 1 | 0.302 | 186 | ||||

| ZWSMD012012-231-X | 12 | 124 | 117 | 89 | 1 | 0.350 | 231 | ||||

| ZWSMD012012-243-X | 12 | 118 | 117 | 80 | 0.8 | 0.350 | 53.8 | 0.35 | 0.41 | 243 | 27.8 |

| ZWSMD012012-326-X | 12 | 88 | 117 | 67 | 0.8 | 0.350 | 326 | ||||

| ZWSMD012012-406-X | 12 | 70 | 117 | 57 | 0.8 | 0.350 | 406 | ||||

| ZWSMD012012-439-X | 12 | 65 | 117 | 54 | 0.8 | 0.350 | 439 | ||||

| ZWSMD012012-546-X | 12 | 52 | 117 | 45 | 0.8 | 0.350 | 546 | ||||

| ZWSMD012012-590-X | 12 | 48 | 117 | 42 | 0.8 | 0.350 | 590 | ||||

| ZWSMD012012-679-X | 12 | 42 | 117 | 38 | 0.8 | 0.350 | 679 | ||||

| ZWSMD012012-734-X | 12 | 39 | 117 | 35 | 0.8 | 0.350 | 734 | ||||

| ZWSMD012012-794-X | 12 | 36 | 117 | 33 | 0.8 | 0.350 | 794 | ||||

| ZWSMD012012-913-X | 12 | 31 | 117 | 29 | 0.8 | 0.350 | 913 | ||||

| ZWSMD012012-987-X | 12 | 29 | 117 | 27 | 0.8 | 0.350 | 987 | ||||

| ZWSMD012012-1135-X | 12 | 25 | 117 | 23 | 0.8 | 0.350 | 1135 | ||||

| ZWSMD012012-1227 | 12 | 23 | 117 | 21 | 0.8 | 0.350 | 1227 | ||||

| ZWSMD012012-1526 | 12 | 19 | 117 | 18 | 0.8 | 0.350 | 1526 | ||||

* The above specifications are subject to change without prior notice. They are for reference only and can be customized as required.