8 mm High Performance Planetary Gearbox

Model: ZWSMD008008

Low Power, High Transmission Efficiency, Lightweight, High Precision

- Diameter

- 8 mm

- Voltage Range

- 12 V

- Reduction Ratio

- 4-1024:1

- Max. Transmittable Power

- 0.84 W

- Max. Continuous Torque

- 0.1 Nm

- Max. Continuous Input Speed

- 12000 rpm

- Bearing at Output

- Ball bearing

- Max. efficiency (%)

- 59-90

- Rated Speed Range

- 25-6375 rpm

- Operating Temperature

- -30…+85℃

Application:

·robot ·smart lock, VR Headsets

·medical technology, precise instrument, Surgical robots

·automotive electronics and more.

Parameters:

| Gearbox Stages | 1 | 2 | 3 | 4 | 5 |

|---|---|---|---|---|---|

| MAX. Continuous output torque (Nm) | 0.01 | 0.02 | 0.06 | 0.08 | 0.1 |

| MAX. Instant mobilization torque (Nm) | 0.015 | 0.03 | 0.09 | 0.12 | 0.15 |

| Reduction ratio | 4 | 16,36 | 64,216 | 256,1296 | 1024 |

| Outer diameter (mm) | 8 | ||||

| Gearbox length (mm) | 5.5 | 8.1 | 10.7 | 13.3 | 15.9 |

| Maximum efficiency (%) | 90 | 81 | 73 | 65 | 59 |

| Recommended temperature range (℃) | -30~+85 | -30~+85 | -30~+85 | -30~+85 | -30~+85 |

| MAX. Gearbox weight (G) | 2.6 | 3.2 | 3.8 | 4.4 | 5 |

| Maximum transmission power (continuous)(W) | 0.84 | 0.52 | 0.39 | 0.13 | 0.04 |

| Maximum transmission power(instantaneous) (W) | 1.05 | 0.65 | 0.49 | 0.16 | 0.05 |

| Air load average empty return (°) | 1.8 | 2 | 2.2 | 2.5 | 3 |

| The maximum axial load (dynamic) (N) | 5 | 5 | 5 | 5 | 5 |

| The maximum radial load (4mm from France) (N) | 5 | 6 | 7 | 8 | 8 |

| Output Bearing | Ball bearing | ||||

| Axial gap (mm) | 0~0.1 | ||||

*Note: The above data does not include the motor, the overall sale of the deceased and the motor, the specific parameters can be customized according to the customer's requirements.

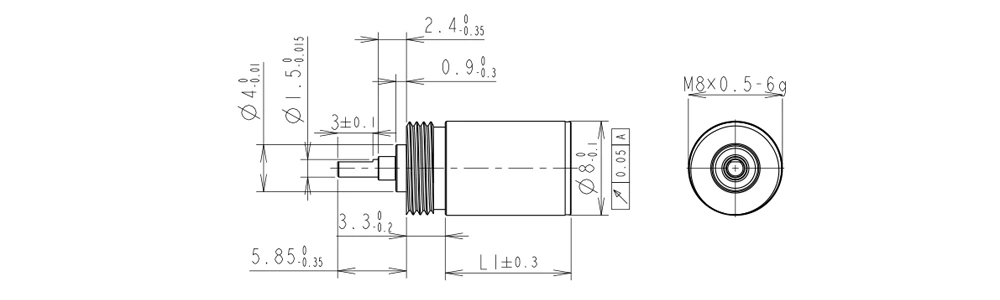

Drawing:

Modular Assembly:

| Combined product | Model | Series | |

|---|---|---|---|

| dc motor | MP0816 Φ8 mm graphite brush | 1-5 | |

| brushless motor | MO0832 Φ8 mm coreless brushless motor | 1-5 | |

| brushless motor | MC0824 Φ8 mm coreless brushless motor | 1-5 | |

| encoder | CB-ST-8 | Magnetic | |

Performance Data:

| Model | Rated voltage | Air load data | Load data | Total length | Gearbox rated torque | Gearbox instantaneous torque |

Reduction ratio |

Gearbox length L1 |

|||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Air -load speed | No-load current | Load speed | Load current | Torque | |||||||

| (V) | (rpm) | (mAmax) | (rpm) | (AMax) | (gf.cm) | (mm) | (NM) | (NM) | / | (mm) | |

| ZWSMD008008-04-X | 12 | 9625 | 120 | 6375 | 0.55 | 100 | 29.5 | 0.01 | 0.015 | 4 | 5.5 |

| ZWSMD008008-16-X | 12 | 2406 | 130 | 1594 | 0.6 | 300 | 32.1 | 0.02 | 0.03 | 16 | 8.1 |

| ZWSMD008008-36-X | 12 | 1069 | 130 | 708 | 0.6 | 80 | 32.1 | 0.008 | 0.012 | 36 | 8.1 |

| ZWSMD008008-64-X | 12 | 602 | 140 | 398 | 0.6 | 600 | 34.7 | 0.06 | 0.09 | 64 | 10.7 |

| ZWSMD008008-216-X | 12 | 178 | 140 | 118 | 0.6 | 200 | 34.7 | 0.02 | 0.03 | 216 | 10.7 |

| ZWSMD008008-256-X | 12 | 150 | 150 | 100 | 0.65 | 800 | 37.3 | 0.08 | 0.12 | 256 | 13.3 |

| ZWSMD008008-1296-X | 12 | 30 | 150 | 20 | 0.65 | 400 | 37.3 | 0.04 | 0.06 | 1296 | 13.3 |

| ZWSMD008008-1024-X | 12 | 38 | 160 | 25 | 0.7 | 1000 | 39.9 | 0.1 | 0.15 | 1024 | 15.9 |

* The above specifications are subject to change without prior notice. They are for reference only and can be customized as required.