ZHAOWEI adopts DC brushless motors for robot vacuum cleaner, because brushless DC motors have obvious characteristics such as high efficiency, high torque, comp...

Drive Systems of Servo Motors for Coding Robots

Micro gearboxes in coding robots tend to require longer service lives, and are more sensitive to noise. Tooth width gear limitations cause helical gears to still produce noise. It’s crucial to emphasize the optimization of gear parameters, and add clutch mechanisms in micro gearboxes. This protects the gears when the robot falls, and the micro gearbox is hit by external impact. ZHAOWEI’s Micro Drive Systems of servo motors for coding robots is able to achieve large transmission ratios in smaller spaces, completing the conversion of transmission shafts to achieve six degrees of freedom (6DoF), and arranges gearbox space reasonably.

Common Motor-Drive Mechanisms in Coding Robots

The driving mechanism of coding robots is differentiated into rotary drive mode, and linear drive mode. The rotary drive mode is most optimal in the structural design, and should be utilized most, due to its strong axis rotation, low friction, and reliability. The joint expansion, located in the joint of the walking mechanism, completely relies on the rotary drive mode, which has the following disadvantages:

- Although the rotational motion can be converted into linear motion, the acceleration of the joint expansion cannot be ignored during high-speed motion. This may end up producing loud noise;

- In order to improve the flexibility of site selection, the linear drive system, which tend to be bulkier and more complex, must be added.

ZHAOWEI Steering Gear Drive Mechanism for Coding Robots

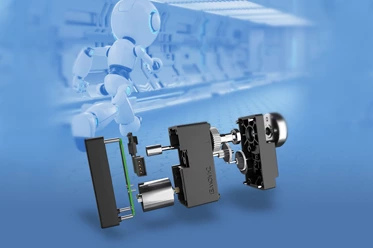

The output gear inside the coding robot steering gear connects to a potentiometer, forming a position sensor. This causes the rotation angle of the steering gear to be affected by the rotation angle of the potentiometer. By connecting the potentiometer to the output gear coupling, the gear ratio can be controlled to fulfill the rotation of the steering gear with a larger range, reducing the error caused by the rotation angle. Small gears lack axial force, so the meshing pinion desensitizes to the axial error. Taking into consideration that planetary gears can achieve large transmission ratios in small spaces, ZHAOWEI uses the 38mm planetary gearhead to control the rotation drive of the coding robot, and uses the 28mm plastic gearhead to control its linear motion. Together, they form the steering gear drive system for the joints of coding robots, which tend to meet the needs of intelligent transmission for joints expansion and movement. This improves the diversity and stability when the steering gear moves.

How Do We Enable the Educational Function of Coding Robots Using the ZHAOWEI Servo Motor Drive System?

In the initial stages, clients commented that coding robots have high requirements, despite their internal gearbox size, and operational performance. Besides, in view of market rates, a high performance-price ratio should be met. These factors pose a huge challenge to ZHAOWEI’s design and manufacturing.

After repeated authentication tests, ZHAOWEI has finally accomplished a micro steering gear transmission structure with high torque. The modules of the planetary gears can be manufactured to M=0.05, with the tooth space thinner than a strand of hair. The ZHAOWEI power steering gearbox has gone through a variety of debugging tests to determine performance. It has shown that it can withstand vibration, impact and high & low temperatures. Low electromagnetic interference and low-noise tests contribute to the product’s ability to produce low-noise, low energy consumption, and long service life. Pertaining to the angle sensor encoder of robots in micro transmission systems, ZHAOWEI has heled the coding robot servo motor gearbox to accomplish the six degrees of freedom control for actions. This can be applied to the angle sensor and gear drive device of the coding robot, which improves its joint control for flexible rotation and movement.

Test-to-Fail: Servo Motor Gearbox for Coding Robots

The reliability and stability of the product is the comprehensive index to evaluate a product’s technical output. In order to analyze, evaluate, verify, and improve product reliability, it is vital to obtain reliable data of assembly and components, including failed test cases. We have created a transmission module laboratory, equipped with multi-functional, experimental equipment, including a vibrator, constant temperature and humidity incubator, thermal shock chamber, box rain test chamber, salt spray test machine, and noise room.

Future Trends

Recently, a number of schools and businesses have increased investments into artificial intelligence (AI) research. The robot steering gearboxes are more extensively applied. Higher requirements of structural and space design should be achieved. On top of improving reliability, it is important to reduce overall production costs, while focusing on elements that include: torsional rigidity, vibration, impact resistance, bearing capacity, and size. This helps meet the six degrees of freedom needed by the transmission of robots more. Both standard types and customizable types are available in ZHAOWEI. For customization services, please contact the online sales, engineers or technicians.

In order to satisfy the ever-changing needs of the market, ZHAOWEI provides a variety of intelligent transmission gearboxes, customized according to our clients’ requirements. From research & development, design, manufacturing to experimental testing, ZHAOWEI firmly strives to help achieve intelligent and high-performing micro drive systems for intelligent robots.

In addition to coding robot, we also provide solutions for robot joint, intelligent robot nurse, educational robot smart base, model airplane, robot vacuum cleaner, robot head rotation and automatic feeder.