ZHAOWEI adopts DC brushless motors for robot vacuum cleaner, because brushless DC motors have obvious characteristics such as high efficiency, high torque, comp...

Servo Motors for Robot Head Rotation

The drive system for robot head rotation allows the robot head move more intelligently, with actions including head shaking, head bending, looking upwards and downwards, etc. This causes the robot's behavior and communication to appear more natural, resulting in an interactive experience.

Drive Demand for Robot Head Rotation

Despite AI advancements, and convenience, robots still sometimes pose some issues. Robot heads are unable to look upwards/downwards, rotate, and their faces aren't expressive, this potentially ruins an experience. Educational robots on the market, for example, generally have display screens added to their faces, allowing them to enhance interactivity. The head rotation device allows the robot head to rotate horizontally, and shake, but most of these robots tend to have poor flexibility, and the control is complicated, leading to high costs.

Simple Drive Systems for Robot Head Rotation

Simple drive systems have been created for robot head rotation, head shaking, and looking upwards/downwards. Power is transmitted through the rack and pinion, allowing the robot to move easily. The robot head, attached to the vertical bevel gear, has two degrees of freedom. It rotates around the vertical axis - controlled by the right stepper motor, and rotates around the horizontal axis - controlled by two stepper motors. Their direction and speed must be equal. The spherical mechanism, where the axes of all five rotating joints are parallel, keeps both motors grounded.

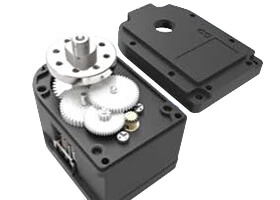

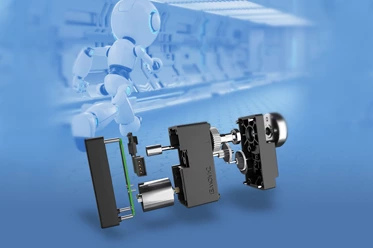

Servo Motors for Robot Head Rotation

The intelligent rotation of the robot head can also be controlled by the servo motor to achieve cw & ccw rotation. The servo motor is a type of micro gear motor, with a relatively simple structure. It consists of a small DC motor, a set of deceleration gears, a potentiometer – that connects to the gear motor to function as a position sensor, and a control circuit board.

Great Heat Dissipation

The motor is needed to drive the rotation of the robot head, and the drive motor tends to generate heat during the driving process. The circuit board operation inside the robot trunk will be affected if the heat fails to dissipate in time, which then affects the robot service life. The ZHAOWEI Servo Motor Drive System can be utilized for intelligent robot head rotation. 2-stage, 3-stage and 4-stage transmissions are available, and can be customized according to our clients' requirements. The reduction ratio, input speed and torque can also be adjusted, allowing the robot head to imitate actions that humans make, prolonging the service life of robot.

Failure Tests of Servo Motors for Robot Head

The reliability and stability of the product is vital in the technical evaluation of the product. In order to accurately analyze, evaluate and verify the performance of each product, ZHAOWEI has built a number of laboratories, which include high/low temperature testing chamber, 3D vibration testing device, thermal shock testing chamber, rain and spray testing chamber, and a rain and spray testing chamber.

Industry Trend

If robots can achieve basic head and facial movements, such as blinking, mouth opening, nodding, etc., they would gain more demand. Nowadays, the use of robot servo motors is becoming more extensive. The demand for service robot reducers mainly comes from small robots - mainly entertainment and educational robots, and large robots - family assistants, collaborative robots. Small robots require gear motors that are more compact, but have high reliability, clutch mechanism, high price/performance ratio, and corresponding small gear modules. Gear motors for large service robots, on the other hand, are designed as a whole with low recoil, high power density, long life, impact resistance, etc. ZHAOWEI believes our Micro Drive Systems will help robot manufacturers create intelligent and technological robots.

In addition to robot head rotation, we also provide solutions for robot joint, intelligent robot nurse, educational robot smart base, model airplane, robot vacuum cleaner, coding robot and automatic feeder.