Impacted by the pandemic, cleanliness now takes on a new meaning. Increasing public awareness regarding health and hygiene and the development of AI, 5G, and Io...

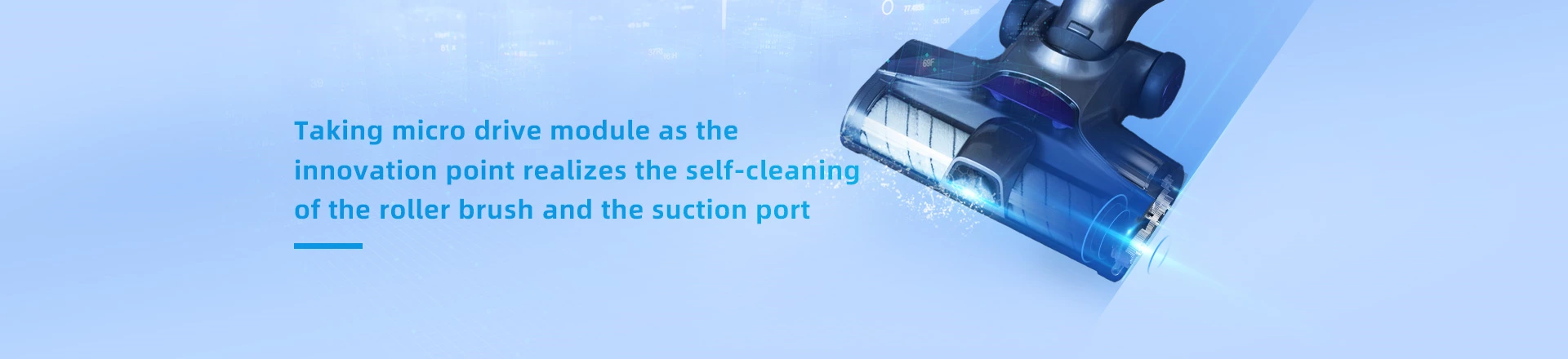

Roller Brush Module for Cordless Handheld Vacuum

Handheld vacuum cleaners are a necessity when it comes to small home appliances. Due to its lower power capacity, suction is not always strong enough. The cleaning capacity of a vacuum cleaner is directly related to the structure of its roller brush, design, and motor suction. The greater the suction, the cleaner the outcome. This however, increases noise and power consumption. The ZHAOWEI roller brush gear motor module for vacuum cleaners is mainly installed in the driving wheel, main brush, side brush, and other moving parts of the vacuum cleaner. They reduce noise production, prolong service life, and increases cleaning efficiency.

Cordless handheld vacuum cleaners have become increasingly popular due to its convenience. Cleaning power also is an important factor that must be considered when purchasing a vacuum cleaner. Most of the new vacuum cleaners on the market are designed with the connector on its tube, resulting in poor flexibility, lack of rotation, and weak suction. The brush head tends to fall off easily, and can cause inconvenience.

Based on thorough R&D, ZHAOWEI, together with smart home appliance manufacturers, have come up with a solution for all the aforementioned issues, and can also improve the quality of dust collection in cordless handheld vacuum cleaners. By adding the high-torque planetary gear motor to the suction head of brush, suction power improves, service life is prolonged, and noise production is reduced.

Design Principle of Rotating Module for Cordless Handheld Vacuum Cleaners

Despite the variety, most cordless handheld vacuum cleaners have similar structures, consisting of a shell, motor, automatic charging base, virtual wall transmitter, sensor head, switch, electric brush, dust bag, etc. The current majority of vacuum cleaner motors mainly utilize AC series excitation motors, and permanent magnet DC brush motors, both of which durability are confined to the service life of the carbon brush. This typically results in shorter service life, bulkier and heavier appliance, and low efficiency, which do not meet market expectation.

Based on the motor requirements of the vacuum cleaner industry (compact size, light weight, long service life, and high performing), ZHAOWEI adds the high-torque planetary gear motor to the suction head of brush. We also make use of the rotating module of cordless handheld vacuum cleaners to control the motor, driving the blade to operate at high speeds, while simultaneously enhancing the dust collection fan. An instantaneous vacuum will be created in the dust collector, leading to a negative pressure gradient against the external atmosphere. This pressure gradient forces the dust and dirt inhaled to be filtered through the dust filter, which then collects in the dust tube. The larger the negative pressure gradient is, the stronger the air volume will be, and the greater the suction capacity it will have. This design allows a strong suction of the cordless handheld vacuum cleaner, and manages the power source efficiently. This helps the brushless motor in the vacuum cleaner increase suction capacity and power, while reducing noise levels, and can be used on most floor tiles, mats, and short-haired carpets. The soft velvet roller simultaneously tackles hair easily, contributing to a deep clean.

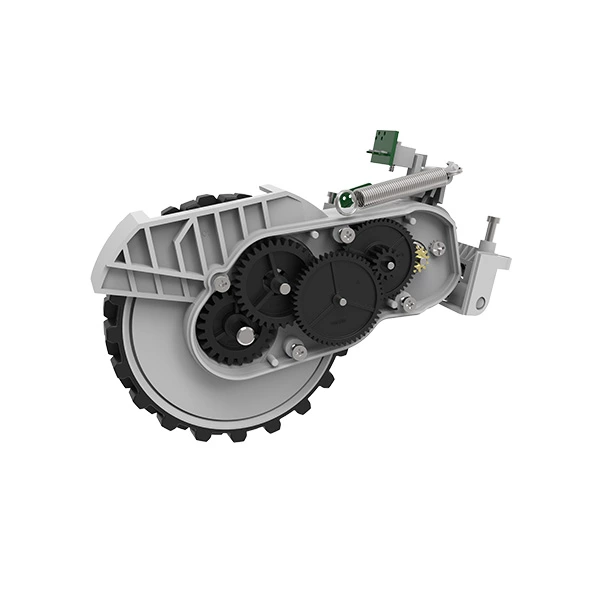

Floors generally require the most frequent cleaning. The 4-stage roller brush gear motor has been configured, by ZHAOWEI, to withstand powerful suction capacity, and can quickly suction dust. 1-stage, 2-stage, 3-stage and 4-stage transmissions are available for the roller brush gear motor module, while the gear ratio, input speed, torque, etc. can be customized according to the clients’ requirements. This meets all factors of intelligent transmission, and enables dust removal to various degrees.

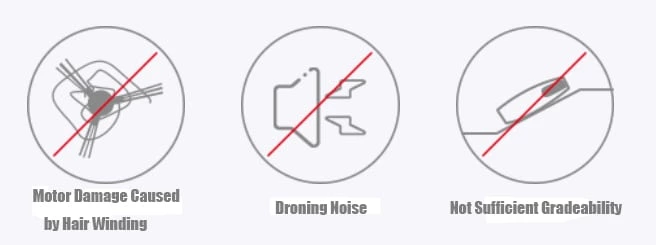

Stable, Low-Noise, Reliable

Handheld vacuum cleaners continue to challenge other types of vacuum cleaners, and its market share across all vacuum cleaner types continue to increase. Previously, the capabilities of handheld vacuum cleaners were updated mainly on the premise of improving their suction capacity. The suction capacity can only develop to a certain degree. Manufacturers have started paying attention to the development of other elements of the vacuum cleaner, including product weight, brush head functionality, anti-jamming technology, multi-functional applications, etc., in order to continue improving user experience.

To prevent the motor getting hair caught in the driving device, and subsequently damaging, we optimized the structure of the main brush gear motor of the vacuum cleaner. The side brush gear motor relies on the meshing of the driving gear and driven gear to transmit the motion and power. Compared to other transmissions, it features wide adaptability, high efficiency, reliable operation, long service life, high precision of gears, low-noise, and dismal vibration.

The development of science and technology has improved the household appliances crucial to our daily lives. An increased offering of vacuum cleaners with varying capabilities have become more available, and has become an important aspect for handheld vacuum cleaners manufacturers to consider for future production. The ZHAOWEI vacuum cleaner gear motor module is mainly used for the driving wheel, main brush, side brush and other moving parts of the vacuum cleaner to acheive low-noise, long service life, and ultimately, high efficiency.

In addition to cordless handheld vacuum, we also provide solutions for peristaltic pump, electric curtain, stroller, smart door lock actuator, rotating screen of TV, sliding cabinet door, window actuator, hard floor cleaner, smart lock, smart toilet pump, smart drawer lock, robot vacuum cleaner, air conditioner front panel, flip trash can, air purifier, automatic pet feeder, smart range hood, TV sliding soundbar, intelligent hot pot cooker, rotating smart speaker, washing machine, automatic toilet seat cover, electric sofa, electric standing desk, sensor pump, TV pop-up camera and electric lifting mosquito net.