The drive system is suitable for strollers that are designed for different age groups, which extend the stroller service life and achieve the function of easy folding and portable carrying.

ZHAOWEI helps your products reach all over the world.

The drive system for stroller adopts the design of brushless motor with parallel transmission gearbox and electric clutch to give the stroller pushing support and achieve automatic braking. When going uphill, the stroller drive system can autonomously drive the stroller for easy pushing. When going downhill, the electric clutch can rapidly brake to avoid random movement.

When going uphill, the stroller can be driven autonomously as an electric bicycle to assit pushing

When leaving hold of the stroller, the brake motor responds in time and the electromechanical lock will engage the brake to avoid the stroller moving.

Driven by the motor, the geared transmission system embed with the solenoid valve to positioning and four-wheel suspension structure and power steering technology to achieve one-handed operation, which enables automatic folding.

ZHAOWEI provides customer-based solutions to meet your needs

Smart travel is not only for the car. Technology Innovation makes the world smarter. ZHAOWEI cares about baby growth and is willing to cooperate with you to improve users' experience.

The market for children's travel is on-growing. ZHAOWEI’s micro drive system will empower the upgrading of strollers. We can help our customers to develop your products and brand and find out new profit methods

More than 20 years of experience in assisting customers in product design. In addition to designing product structure, we can assist customers to explore unique product functions to quickly seize market share.

The micro drive system for stroller is one of the key technology that will not only meet the customer’s needs also help to upgrade the product

We protect the business interests of each partner. We promise that will not sell customers' customized products to the public.

ZHAOWEI has Smart Control Laboratory, Transmission System Laboratory, and Gear Testing Laboratory, controlling products quality from transmission design, tooth design, strength check, CAE simulation, noise analysis, and other dimensions.

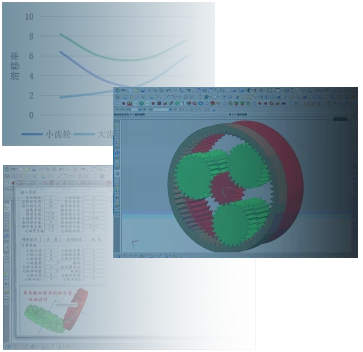

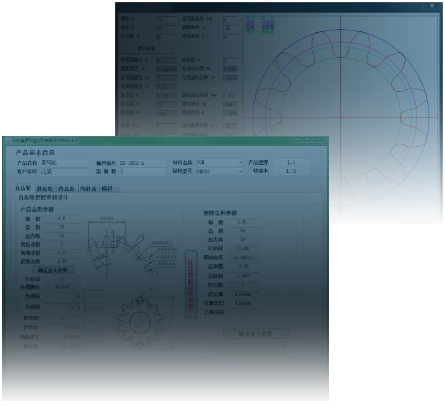

The self-developed micro drive design software covers a variety of transmission forms of rapid precision modeling greatly improving the development efficiency.

Modification coefficients selection

All-in-one parameter design

Efficiently and precisely molding

Designing gear tooth profile by ZHAOWEI self-developed software to achieve details design such as gear parameters design and micro-geometrical design.

Shaping gears and doing parametric design through ZHAOWEI's strong database.

Gear tooth profile

design software

Parametric tooth design

for mold cavities

Checking bending fatigue strength gears of different materials under different working conditions based on the gear transmission software to analyze and optimize gear tooth contact stresses.

Gear strength check

Gear tooth contact analysis

Mechanical simulation analysis of the transmission system based on customer requirements.

Drop simulation of the miniature

transmission system

Gearbox shell modal simulation

Influence of tooth root filtration curve

on tooth root bending strength

Simulation of transient contact force of

helical gear pair under different side gap

Influence of tooth top fillet angle on

contact stress during the reverse drive

Sound vibration analysis with Danish B&K acoustic analysis system

Paulse - experimental modal analysis

Connect - gearbox waterfall diagram analysis

Gearbox noise spectrum analysis

This website uses anonymous performance cookies to ensure you get the best experience on our website. We never use targeting or advertising cookies. Find out more: Cookies Policy