VR micro drive system solutions provider

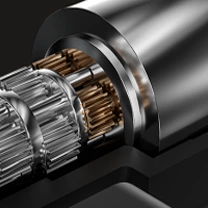

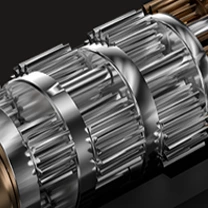

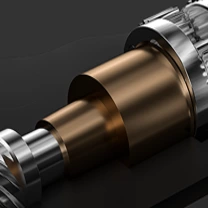

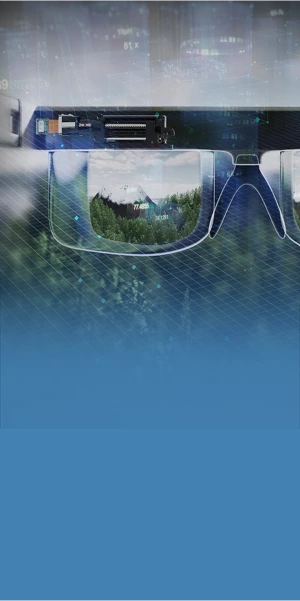

Different from the normal product, many premium headsets adopt inner sensors to convert data into electric drive signals. When users wear the headset, the sensors will receive the signals that the useris gazing at the lens, then the micro electric adjustment mechanism automatically change the rotary motion into the pushrod rectilinear motion to drive the lens automatically focusing on the user's appropriate pupil distance. The electric adjustment can give users a perfect wearing experience.

Today, the normal headset on the market mostly is composed of plastic rack gear transmission and manually adjust IPD by moving the middle gear to drive the rack and lens moving left and right according to the users' needs. However, the manual adjustment will result in visual dizziness because of low precision, which can’t provide a positive experience.

Through micro drive module driving lens, the product realizes VR headset intelligent IPD adjustment and improves accuracy to satisfy customers’ requirement of fine-adjusting, which enhancesthe users' experience.

• Technical Difficulties:

1.The control accuracy of the micro drive mechanism must be accurate to 1S go 0.05mm stroke,

2.The inner sensors must ensure two lens module moving synchronization.。

• Technical Application:

When users wear the headset, the IPD drive system will automatically measure the user's pupil distance and adjust the distance between the two lenses until it moves to the user's suitable pupil distance to improve the users' experience. Also, users can also manually adjust distance according to viewing habits.