VR technology is increasingly growing as a crucial role in various fields, including game, healthcare, construction, business, etc. Have you wondered about the ...

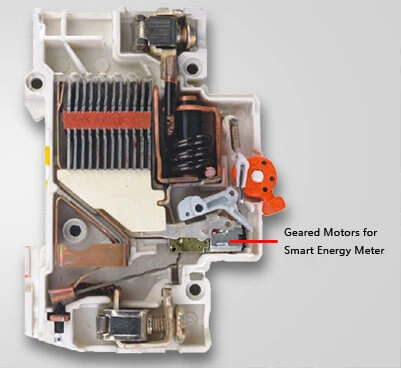

Geared Motors for Smart Energy Meter

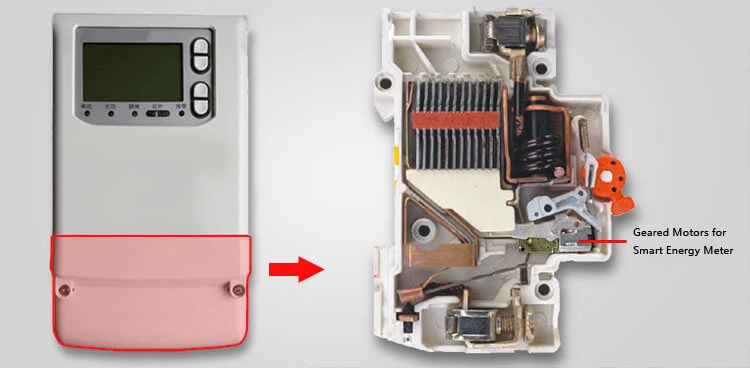

With the acceleration of the development and utilization of electric energy, smart terminals of smart grids have gradually begun to deploy smart meters with functions such as electric power measurement and timing, billing, communication with master computers, and power management. At present, smart meters can be roughly divided into two categories: electromechanical energy meters and electronic energy meters. With our micro gear drive system, energy meters can managed and used intelligently.

ZHAOWEI Electromechanical Energy Smart Meter Drive System

The electromechanical energy meter uses an electronic metering circuit to obtain a digital pulse signal and then uses a micromotor to drive the code wheel to obtain the energy count value. This structure is simple and feasible for an electronic meter, but the requirements of the circuit are high. All meters need to convert the electric energy value into a corresponding number of digital pulses according to a fixed ratio, then the micromotor rotates the code wheel.

Currently, in order to improve the accuracy of the meter and the consistency of the product, electromechanical energy meters on the market need a high amount of human and material resources in the production process to screen the components and adjust the semi-finished products, resulting in long production cycles and high costs.

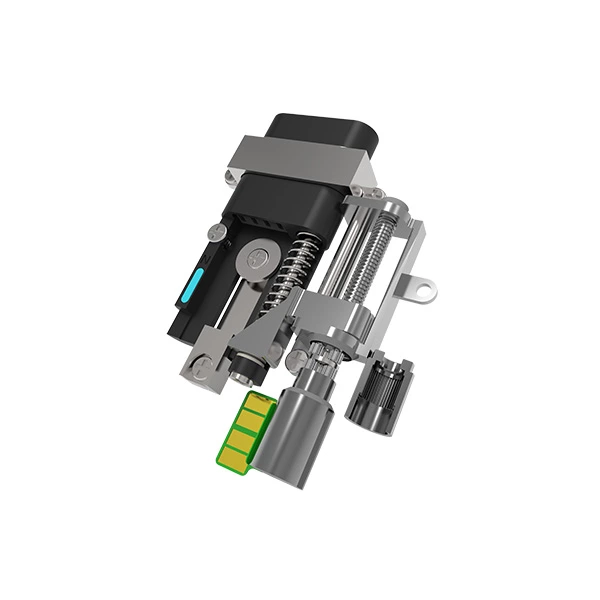

In order to solve this problem, we have added a gear reduction motor in front of the micro motor drive system with an electronic counting device. The planetary gearbox structure is used to optimize the electronic count device of the code wheel drive system. It also works to stabilize the code wheel driven by the micro motor and solve problems related to concentricity and uniform speed of small-volume products, allowing each meter to convert the electric energy value into a corresponding number of digital pulses according to a fixed ratio and driving the micromotor to rotate the character wheel at the correct speed. In order to achieve automatic metering and billing and control, it greatly reduces the production cost and cycle and solves the problem of the correct reading of smart meters.

Smart Energy Meter

Geared Motors for Smart Energy Meter

ZHAOWEI Electronic Energy Meter Drive System

Electronic energy meters are smaller, more reliable and consume less power than electromechanical energy meters, but the service life and reliability of electronic energy meters need to be urgently improved.

The failure mechanism of electronic energy meters is not the same as that of mechanical energy meters. The failure mechanism of mechanical energy meters is of the mechanical wear type. Once a failure occurs, the meter is still able to provide power and its impact is relatively small. The failure mechanism of electronic energy meters is sporadic. Once a failure occurs, it may lead to the loss of electricity, display issues, or loss of historical measurement data, which will bring immeasurable economic losses to the power grid. At the same time, electronic energy meters have disadvantages like poor anti-interference features.

To solve this problem, we’ve added an intelligent self-locking function to the circuit breaker controller of the electronic energy meter. Considering that the stable operation of the loop control system can be driven in a limited space of the meter’s smart controller and only the rotation in the specified direction is allowed, we’ve adopted a 10mm planetary gearbox and turbine inserts with injection molding for the loop controller gearbox. Thus, the transmission structure has a small volume, high torque, and a self-locking function.

The circuit controller gearbox in this design can carry out reverse self-locking of the electronic energy meter, which can transmit the power of the active end of the motor without responding to external loads, thereby isolating the external load and preventing it from affecting the smart meter’s own mechanisms. When encountering possible damage, the ZHAOWEI smart meter gear motor (also called loop controller gear motor) will stop automatically, which improves its service time, avoids the problem of data loss during a sudden power failure, and protects data security.

ZHAOWEI Gearbox Specification for Smart Energy Meter

Voltage: 1.5V

Reduction Ratio: 171:1

No-load Current: ≤160mA

No-load Speed: 30±15%rpm

Working Temperature: -30℃–80℃

Noise: ≤50 dB

The transmission stage, reduction ratio, output speed, and torque of gearboxes for smart energy meters can be customized according to customer requirements.

In addition to smart energy meter, we also provide solutions for base station smart cabinet lock, base station antenna, all-screen phone camera, PTZ camera, phone rotating camera, Pan&Tilt Heads , VR headset and video conference equipment.